When embarking on a furniture or cabinetry project, one of the most crucial decisions you’ll face is selecting the right materials. Among the many options available, cabinet grade plywood consistently stands out as the material of choice for both professional woodworkers and DIY enthusiasts. This high-quality plywood is specifically designed for cabinetry and furniture construction, providing strength, stability, and aesthetic appeal. But what exactly makes cabinet grade plywood so exceptional compared to other plywood types? And why is it considered the go-to choice for high-end cabinetry?

This guide will explore the characteristics, advantages, and different types of cabinet grade plywood, explaining why it is the best option for your next furniture or cabinetry project. With its smooth finish, durability, and versatility, cabinet grade plywood can take your designs to the next level.

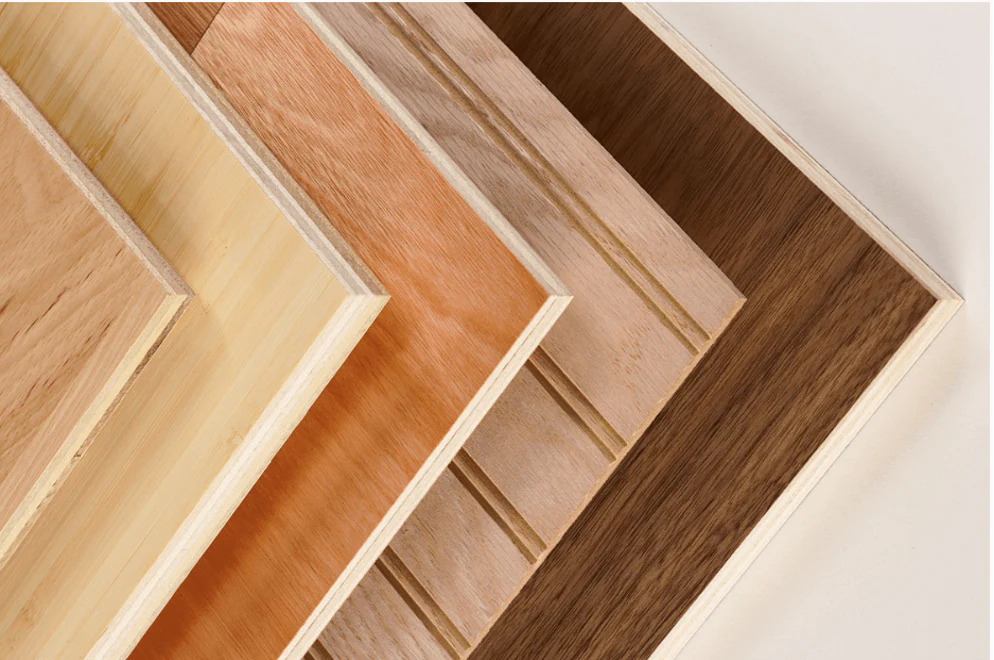

What is Cabinet Grade Plywood?

Cabinet grade plywood refers to a high-quality plywood that has been specifically engineered for use in cabinetry and fine furniture making. Unlike standard plywood, which can have visible defects and uneven surfaces, cabinet grade plywood is meticulously manufactured to meet high standards. It is often composed of multiple layers of veneer, providing exceptional strength, while the outer layers (veneers) are carefully selected for aesthetic appeal.

This type of plywood is a preferred choice for projects requiring both structural integrity and an attractive finish. It’s highly valued in woodworking for its smooth surface, which makes it perfect for finishing with paint, stain, or other decorative treatments. Cabinet grade plywood is designed for those who prioritize precision and quality in their work, whether they are crafting custom kitchen cabinets, bathroom vanities, or unique furniture pieces.

In many cases, cabinet grade plywood is also referred to as furniture-grade plywood, premium plywood, or high-quality plywood. These terms underscore the exceptional quality of the product and its suitability for high-end cabinetry and furniture projects.

The Importance of Using High-Quality Plywood in Furniture Making

The quality of materials used in furniture and cabinetry construction plays a direct role in the final product’s longevity, strength, and appearance. Cabinet grade plywood offers numerous advantages over lower-quality plywood and solid wood alternatives. Its superior characteristics — such as smoothness, strength, and resistance to warping — make it the ideal choice for projects that require both durability and an aesthetically pleasing finish.

For example, premium plywood can withstand the stresses and strains of daily use, making it an excellent choice for high-traffic areas like kitchens and bathrooms. The material’s fine veneer layers allow it to be easily sanded, stained, or painted, providing a flawless finish every time. As a result, cabinet-grade plywood is essential for achieving that professional, high-end look that is so desirable in modern furniture and cabinetry.

The Composition of Cabinet Grade Plywood

The exceptional quality of cabinet grade plywood is the result of careful manufacturing processes that combine fine veneers with strong core materials. Understanding the composition of this material helps explain why it is the best choice for high-end furniture and cabinetry.

Core Materials

At the heart of cabinet grade plywood lies its core, which consists of layers of different materials depending on the intended use. The core plays a crucial role in providing strength, stability, and structural integrity to the plywood. Below are some of the most common core materials found in cabinet-grade plywood:

- MDF (Medium-Density Fiberboard) Core: MDF is known for its smooth, uniform surface, making it an excellent option for projects that require a flawless finish. MDF-core plywood is highly stable, as it is less likely to warp or expand with moisture. This is particularly beneficial for cabinetry that will be painted or veneered, as the smooth surface ensures better adhesion of the finish.

- Hardwood Core: Hardwood-core plywood is made by layering solid wood veneers, such as maple, oak, or birch, to create a robust and durable core. This type of core provides exceptional strength and is commonly used in applications where the plywood will bear significant weight or undergo heavy usage. Hardwood-core plywood is often favored for premium furniture pieces, custom cabinets, and built-ins due to its superior structural integrity.

- Particleboard Core: Particleboard is an engineered wood product made from wood chips and resin. While it is often used in lower-quality plywood, particleboard-core plywood can be found in certain cabinet-grade plywood types for specific applications. Although it may not offer the same strength as MDF or hardwood cores, particleboard can still provide a stable base for more cost-effective furniture or cabinetry projects.

Veneers

The outer layers of cabinet grade plywood are made from thin sheets of wood called veneers. Veneers are typically made from hardwoods such as oak, maple, cherry, or birch, though other species can be used depending on the desired aesthetic. The veneer layers are bonded together using a strong adhesive to form the plywood sheet.

The quality of the veneer plays a significant role in the overall appearance and durability of cabinet-grade plywood. Furniture-grade plywood uses high-quality veneers that are free from defects such as knots, cracks, or discoloration. These veneers can be sanded to a smooth finish, allowing for an even application of paint or stain.

In addition to the aesthetic value, the thickness of the veneer is another critical factor in determining the strength of cabinet-grade plywood. Thicker veneer layers are more durable and provide a better finish when sanding or refinishing. Fine-grade plywood typically features thicker veneers, which enhance both its visual appeal and structural integrity.

Bonding and Adhesives

The strength of cabinet-grade plywood depends largely on the quality of the adhesives used to bond the veneer layers together. The adhesive used in the plywood manufacturing process ensures that the layers of veneer are securely bonded and resistant to moisture, temperature changes, and everyday wear and tear.

Common adhesives used in premium plywood manufacturing include:

- Phenolic Resin: Phenolic adhesives are known for their water-resistant properties and durability. They are often used in high-quality plywood products that will be exposed to moisture or humidity.

- Urea-Formaldehyde: This adhesive is commonly used in cabinet-grade plywood due to its strong bonding characteristics. It is less resistant to moisture than phenolic resin but is still widely used for interior furniture and cabinetry applications.

The strength of the adhesive bond contributes to the overall stability of cabinet-grade plywood, ensuring that the finished product will withstand the test of time.

Key Characteristics of Cabinet Grade Plywood

Cabinet-grade plywood is valued for its exceptional qualities, which set it apart from other types of plywood. These characteristics make it ideal for furniture and cabinetry projects that demand both durability and aesthetic appeal.

Smooth Finish

One of the standout features of cabinet-grade plywood is its smooth, even surface. The multiple layers of thin veneers are meticulously sanded to create a uniform, defect-free surface, perfect for painting, staining, or veneering. This smooth finish is particularly important for visible cabinetry or furniture, as it ensures that the final product will have a polished, professional appearance. Whether you’re crafting custom kitchen cabinets or a unique bookshelf, cabinet-grade plywood provides a flawless foundation for any finish.

Strength and Durability

Cabinet-grade plywood is built to last. Its multi-layered construction gives it remarkable strength and resistance to warping, cracking, or splitting. The layers of veneer are bonded tightly together, creating a robust material that can withstand the stresses of everyday use. This makes cabinet-grade plywood an ideal choice for furniture and cabinetry that will be subjected to weight, pressure, and handling over time.

Because of its durability, cabinet-grade plywood is also less likely to develop defects such as bowing or cupping, even in environments with fluctuating temperatures or humidity levels. This stability ensures that your cabinetry or furniture pieces will maintain their form and function for years to come.

Aesthetic Appeal

The visual quality of cabinet-grade plywood is another reason why it’s favored for high-end cabinetry and furniture. The fine veneer layers contribute to an elegant and consistent appearance, with a smooth texture and natural wood grain that adds warmth and beauty to any space.

The veneer can be selected from a wide range of wood species, each with its own unique grain patterns, color tones, and textures. Whether you choose light-colored maple or rich, deep cherry, premium plywood allows you to create a finished product that complements your style and design preferences. This versatility is especially important for custom furniture and cabinetry projects that require a high-end look.

Moisture Resistance

Moisture resistance is an essential quality for plywood used in cabinetry, particularly in environments like kitchens and bathrooms where humidity levels can fluctuate. Cabinet-grade plywood is often treated with special adhesives and coatings to ensure that it resists moisture absorption. This moisture resistance prevents warping, swelling, or delamination, which can compromise the appearance and durability of the finished product.

The ability to withstand moisture makes cabinet-grade plywood an excellent option for bathroom vanities, kitchen cabinets, and any other furniture or cabinetry that will be exposed to water or humidity.

Types of Cabinet Grade Plywood

Different types of cabinet-grade plywood offer unique benefits that suit various applications. Whether you’re constructing custom kitchen cabinets, shelving, or furniture, selecting the right type of plywood is essential for achieving optimal results.

Hardwood Plywood

Hardwood plywood is crafted from solid hardwood veneers, such as oak, maple, cherry, or birch. This type of furniture-grade plywood offers superior strength and durability, making it ideal for high-end cabinetry and furniture. Hardwood plywood is prized for its ability to hold stains and finishes beautifully, allowing for a refined, polished look that enhances the overall aesthetic of your project.

MDF Core Plywood

MDF-core plywood is a popular choice for projects that require a smooth, even surface. The smoothness of the MDF core makes it ideal for cabinetry that will be painted or veneered. Although MDF-core plywood lacks the strength of hardwood-core plywood, it offers excellent dimensional stability and a flawless surface, making it a favorite for decorative applications.

Baltic Birch Plywood

Baltic birch plywood is known for its exceptional strength and stability. With a dense, uniform grain, this type of plywood is highly durable and resistant to warping, making it ideal for high-end cabinetry, shelving, and custom furniture. The consistent thickness of Baltic birch plywood also makes it an excellent choice for projects that require precise cuts and a uniform appearance.

Laminated Veneer Lumber (LVL) Core Plywood

Laminated Veneer Lumber (LVL) is an engineered wood product that offers outstanding strength. LVL core plywood is often used for structural applications, such as shelving or heavy-duty cabinetry. The high strength of LVL core plywood makes it ideal for custom storage solutions and built-ins that need to bear significant weight.

Benefits of Using Cabinet Grade Plywood for Furniture Making

Using cabinet grade plywood offers a wide array of advantages, making it a favored choice among both professionals and DIY enthusiasts. Here are some of the key benefits that set cabinet-grade plywood apart from other materials.

Cost-Effectiveness

While cabinet-grade plywood may come with a higher price tag compared to regular plywood, it’s important to consider its long-term value. When compared to solid wood alternatives, cabinet-grade plywood offers a more affordable option without sacrificing strength, aesthetics, or durability. The cost savings come from its engineered structure, which allows for superior stability and strength without the need for solid wood panels that would otherwise be expensive and prone to warping.

Additionally, because cabinet-grade plywood is easier to work with than solid wood, it reduces labor costs and time spent on finishing. The smooth surface of high-quality plywood requires less sanding and preparation, leading to a more efficient production process and fewer finishing errors.

Precision and Consistency

Another key advantage of cabinet-grade plywood is its ability to maintain a consistent thickness and grain pattern throughout the sheet. This precision ensures that each panel fits seamlessly in your design, whether you’re building cabinets, shelves, or custom furniture. The manufacturing process of cabinet-grade plywood involves strict quality control, ensuring that each sheet is uniform and free of defects.

For cabinetmakers and woodworkers, this consistency is critical, as it guarantees that each piece will align perfectly with others, leading to a more professional and aesthetically pleasing result. Whether working with premium plywood or fine-grade plywood, the uniformity of the material makes it much easier to achieve exact dimensions and a flawless finish.

Environmental Sustainability

In today’s world, sustainability is an important consideration when selecting materials for any project. Cabinet-grade plywood often comes from sustainably sourced wood, with many manufacturers adhering to environmental standards such as the Forest Stewardship Council (FSC) certification. FSC-certified plywood is made from wood that comes from responsibly managed forests, ensuring that the production of the material doesn’t harm the environment.

In addition to its sustainable sourcing, premium plywood is also more efficient in terms of material usage. Unlike solid wood, which can require the cutting down of large trees, plywood is made by layering thin sheets of veneer, meaning fewer trees are needed to produce the same amount of material. As a result, choosing cabinet-grade plywood is a more environmentally responsible choice compared to other materials.

Ease of Handling and Workability

One of the standout qualities of cabinet-grade plywood is how easy it is to work with, especially for those who are tackling DIY projects or large-scale professional builds. Furniture-grade plywood is lightweight compared to solid wood, making it easier to transport, cut, and handle. The precision of premium plywood also allows for accurate cuts and smooth edges, minimizing the amount of work needed to achieve a finished product.

Cabinet-grade plywood is also easier to shape and finish, making it an excellent choice for custom cabinetry and intricate furniture designs. It can be easily cut to size, and its smooth surface allows for a flawless paint or stain finish, ensuring that the end result looks professional without requiring excessive effort.

How to Choose the Best Cabinet Grade Plywood

Choosing the right cabinet-grade plywood for your project is essential for achieving the best results. There are several factors to consider when selecting premium plywood, including wood species, thickness, veneer quality, and the grade of plywood.

Consider the Wood Species

Different wood species offer different aesthetic qualities and levels of durability, so selecting the right species for your project is crucial. Popular species used in cabinet-grade plywood include:

- Maple: Known for its light color and fine grain, maple is an excellent choice for those seeking a clean, modern look.

- Oak: A traditional hardwood with a strong, open grain, oak is a durable and versatile option often used for rustic-style cabinetry.

- Birch: Offering a smooth surface and a light, even color, birch plywood is a great choice for projects where a consistent finish is essential.

- Cherry: A rich, reddish-brown wood that darkens with age, cherry adds a touch of luxury to any project.

When selecting cabinet-grade plywood, take the time to assess the wood species that best aligns with the overall aesthetic you want to achieve. Some woods may be more suitable for staining, while others may have better durability for structural components.

Selecting the Right Thickness

The thickness of cabinet-grade plywood can greatly impact the strength, weight, and stability of your project. Common thicknesses for furniture-grade plywood include:

- 1/4 inch: A thinner plywood ideal for lightweight applications such as drawer bottoms, cabinet backs, or decorative panels.

- 1/2 inch: A medium thickness commonly used for cabinet shelves, panels, and partitions.

- 3/4 inch: The thickest and most robust option, ideal for building cabinet boxes, doors, and other high-load applications.

The thickness you choose will depend on the specific requirements of your project. For heavier-duty cabinetry or furniture, opt for thicker cabinet-grade plywood to ensure the material can withstand the stresses placed upon it.

Quality of Veneer

The veneer is one of the most important aspects of cabinet-grade plywood. The quality of the veneer directly impacts the appearance of the finished project. When selecting furniture-grade plywood, look for veneer that is free from defects such as knots, discoloration, or cracks. High-quality veneers will ensure a smooth, even finish and provide a uniform appearance for painting or staining.

Examine the veneer closely to check for any signs of imperfections. While small knots or slight color variation can add character to a project, visible defects can compromise the overall look and reduce the plywood’s value.

Grade of Plywood

As mentioned earlier, cabinet-grade plywood is typically graded from A to D, with A-grade plywood being the highest quality. The grade of the plywood determines its appearance and suitability for different applications:

- A-grade: A smooth, flawless surface with minimal imperfections. Ideal for visible parts of cabinets and furniture.

- B-grade: Slight imperfections, such as small knots or patches, that can be repaired. Suitable for applications where the surface won’t be prominently visible.

- C-grade: Contains larger defects and visible repairs. Best suited for structural applications where the surface will be concealed.

For most high-end cabinetry or furniture projects, A-grade plywood is the best choice. However, if you’re working on hidden areas or parts of your project that will be covered by other materials, B-grade plywood may be sufficient.

Common Applications of Cabinet Grade Plywood

Due to its strength, durability, and aesthetic qualities, cabinet-grade plywood is used in a variety of applications. Whether you’re building custom furniture, cabinets, or other wood-based structures, this material provides the reliability and professional finish that is needed for high-quality results.

Kitchen Cabinets

One of the most popular uses for cabinet-grade plywood is in kitchen cabinetry. It’s perfect for both the structural framework and the visible surfaces of cabinets. The smooth finish ensures that the cabinets can be painted, stained, or veneered to suit any design. Additionally, cabinet-grade plywood is durable enough to withstand the wear and tear associated with kitchen use, including heavy dishes, cookware, and daily traffic.

Bathroom Cabinets

In bathrooms, cabinet-grade plywood is a must-have due to its moisture resistance. Bathrooms are exposed to high levels of humidity and moisture, which can cause other materials to warp or degrade. Premium plywood, however, holds up well under these conditions, making it the perfect material for bathroom vanities and storage units.

Furniture Manufacturing

Beyond cabinetry, cabinet-grade plywood is widely used in the production of furniture. Its versatility and ability to take on various finishes make it ideal for creating custom pieces such as bookshelves, dressers, and entertainment centers. The superior strength of professional-grade plywood also ensures that these furniture items are built to last.

Built-ins and Shelving

Custom built-ins, such as closets, storage units, and shelves, benefit from the use of cabinet-grade plywood. The material’s strength allows it to handle heavy loads while maintaining a polished, professional appearance. Whether you’re creating a media center or a wall-mounted bookshelf, top-tier plywood ensures that the project is both functional and visually appealing.

Installation and Finishing Tips

Once you’ve selected the perfect cabinet-grade plywood for your project, the next step is installation and finishing. Whether you’re assembling cabinets, building furniture, or constructing custom shelving, there are key techniques to keep in mind that ensure a flawless end result. Below are some essential tips for working with furniture-grade plywood.

Cutting and Sizing

Cutting cabinet-grade plywood to the correct dimensions is an essential first step in ensuring that your project fits together perfectly. When cutting plywood, always use a sharp blade to minimize splintering on the edges. A table saw or circular saw is often the best choice for straight, precise cuts. However, for more intricate or curved cuts, a jigsaw or router might be necessary.

Before cutting, measure and mark your plywood sheets carefully. Double-check your measurements to ensure that each piece will fit together as intended. It’s also a good idea to cut all of your pieces at once to ensure consistency in your project.

To minimize the risk of splintering, consider applying painter’s tape along the cut lines. This will help support the veneer during the cutting process and prevent it from lifting, resulting in a cleaner edge.

Sanding and Surface Preparation

After cutting, the next step is to prepare the surface of cabinet-grade plywood for finishing. Sanding is crucial to remove any rough spots and ensure an even, smooth surface. For best results, start with a medium-grit sandpaper (around 120-grit) and work your way up to a finer grit (220-grit) to create a silky-smooth finish.

Always sand in the direction of the grain to avoid scratching the surface. If you’re preparing the plywood for staining or painting, make sure the surface is dust-free by wiping it down with a clean, damp cloth or tack cloth after sanding.

Proper sanding ensures that any finish — whether paint, stain, or clear coat — will adhere well to the surface of the plywood, providing a durable and beautiful end result.

Edge Banding

When working with cabinet-grade plywood, the edges often require attention, as plywood edges can appear rough or unfinished. Edge banding is a simple and effective way to give plywood edges a polished, professional look. Edge banding comes in a variety of materials, including wood veneer, PVC, and melamine, and can be applied using an iron or adhesive.

To apply edge banding, simply align the strip along the edge of the plywood and press it into place with heat or adhesive. Once the edge banding is applied, trim off any excess and use a fine-grit sandpaper to smooth the edges. The result is a clean, seamless finish that elevates the overall appearance of your project.

Staining and Sealing

Staining and sealing cabinet-grade plywood allows you to enhance the wood’s natural beauty and provide protection against moisture, dirt, and wear. The smooth surface of furniture-grade plywood makes it an ideal candidate for staining, as it allows the color to be absorbed evenly.

Before applying stain, test it on a small, inconspicuous area to ensure that the color is what you expect. Once you’re satisfied with the result, apply the stain evenly with a brush or cloth, following the direction of the grain. Allow the stain to dry completely before applying a protective topcoat.

After staining, seal the plywood with a clear finish, such as polyurethane or lacquer, to protect the surface from damage. A polyurethane finish provides a durable, water-resistant coat that is perfect for high-traffic areas like kitchens and bathrooms.

Care and Maintenance of Cabinet Grade Plywood

To ensure that your cabinet-grade plywood projects remain beautiful and functional for years to come, proper care and maintenance are essential. Below are some guidelines to help you maintain your premium plywood furniture and cabinetry.

Cleaning and Maintenance

Cleaning cabinet-grade plywood is relatively simple, but it’s important to avoid harsh chemicals or abrasive cleaners that could damage the surface. For routine cleaning, use a soft cloth or sponge with mild soap and water to wipe down surfaces. Avoid using excessive moisture, as this can cause the plywood to warp or swell over time.

If your cabinetry or furniture is stained or marked, use a specialized wood cleaner or polish to restore its shine. Always follow the manufacturer’s instructions on any cleaning products to ensure they are safe for use on cabinet-grade plywood finishes.

Repairs

Despite its durability, cabinet-grade plywood can occasionally suffer from minor damage, such as chips, scratches, or dents. Fortunately, repairs are usually simple and can restore the plywood to its original condition.

To repair scratches or small chips, you can use wood filler or putty in a color that matches the plywood’s finish. Apply the filler carefully, smooth it out with a putty knife, and allow it to dry completely before sanding it smooth. After sanding, touch up the repaired area with paint or stain, as necessary.

For more significant damage, such as deep gouges or large cracks, you may need to replace the affected section of plywood or consult a professional for assistance.

Moisture and Temperature Considerations

Although cabinet-grade plywood is designed to withstand moisture, prolonged exposure to high humidity or drastic temperature changes can cause the material to warp or swell. To avoid this, ensure that your plywood is sealed properly, particularly in areas like kitchens, bathrooms, or basements.

It’s also important to control the climate in areas where cabinet-grade plywood is used. Using a dehumidifier in bathrooms or kitchens can help prevent excessive moisture buildup, while regulating indoor temperatures can prevent expansion and contraction of the plywood.

For outdoor applications, make sure to use premium plywood that has been treated for exterior use or coat it with a protective finish to withstand the elements.

Conclusion

In conclusion, cabinet-grade plywood is an exceptional material for cabinetry and furniture making due to its superior strength, smooth finish, and aesthetic versatility. From kitchen cabinets to custom furniture, premium plywood offers durability and a beautiful surface that is ideal for both functional and decorative pieces.

By understanding the composition, characteristics, and various types of cabinet-grade plywood, you can make informed decisions about the materials that will best suit your project’s needs. Whether you are a professional woodworker or a DIY enthusiast, choosing furniture-grade plywood ensures that your final product will be both long-lasting and visually appealing.

Ultimately, cabinet-grade plywood allows you to create custom furniture and cabinetry that stands out for its strength, beauty, and craftsmanship. By following the right installation, finishing, and maintenance practices, your projects will remain stunning for years to come.

Choosing cabinet-grade plywood is an investment in quality, and with the proper care, it will continue to enhance your home or workspace for a lifetime.