Wood glue is a vital tool for anyone involved in woodworking, whether you’re a seasoned carpenter, DIY enthusiast, or a hobbyist. Knowing how strong is wood glue is can greatly influence the quality and durability of your projects. This guide will cover everything you need to know, from the different types of wood glue to factors affecting its strength, and offer practical advice for achieving the best results.

Types of Wood Glue

When selecting wood glue, it’s important to understand that not all adhesives are the same. Each type has unique properties that make it better suited for specific tasks. The strength of wood glue varies significantly depending on the kind you choose.

PVA Glue (Polyvinyl Acetate)

PVA glue, also known as white glue, is the most commonly used wood glue.

- Common Uses: PVA glue is commonly used in a variety of projects, such as crafting, furniture making, and general woodworking. It’s an excellent choice for indoor woodworking projects that don’t require extreme durability.

- Pros and Cons: It’s easy to use, dries relatively fast, and is affordable. However, its major downside is its sensitivity to moisture. If exposed to humidity or water, the bond can weaken, making it less suitable for outdoor or high-moisture environments.

- Strength Characteristics: PVA glue forms a solid bond between wood pieces, with enough strength for most basic woodworking tasks. However, it is not as resilient as more specialized adhesives, especially in harsh conditions.

Epoxy Glue

Epoxy glue is widely regarded as one of the strongest adhesives available.

- Common Uses: Epoxy is ideal for heavy-duty woodworking projects, such as outdoor furniture, boat repairs, and applications that require a high degree of durability. It is also often used for repairs on surfaces that are difficult to bond.

- Pros and Cons: Epoxy glue offers excellent strength, resistance to water, heat, and chemicals, and provides a durable bond that is difficult to break. However, it has a long curing time and is more complex to mix and apply.

- Strength Characteristics: When fully cured, epoxy glue provides a bond that is stronger than the wood itself. This makes it an excellent choice for high-stress applications, where strength and reliability are essential.

Polyurethane Glue

Polyurethane glue is another strong adhesive, often used in more demanding tasks.

- Common Uses: Polyurethane glue is often chosen for projects that involve bonding wood to metal, stone, or other materials. It is also useful in applications where water resistance is critical.

- Pros and Cons: One of the key benefits of polyurethane glue is that it expands as it cures, filling any gaps in the joint. However, this can sometimes make it messy to work with, and it has a longer curing time compared to other glues.

- Bond Strength Details: Polyurethane glue creates a very strong bond that can hold up well in both dry and wet conditions. Its ability to bond wood to other materials like metal and plastic makes it a versatile choice for various projects.

Hide Glue

Hide glue is a traditional adhesive that has been used in woodworking for centuries.

- Strength Characteristics: Although it doesn’t have the same strength as modern adhesives like epoxy or PVA, hide glue is still incredibly strong, especially in fine woodworking applications. It is a natural glue made from animal collagen and is valued in restoration and antique furniture repair.

- Comparison to Modern Adhesives: While hide glue is weaker than synthetic alternatives, its ability to form a strong bond with wood and be reversible makes it a favorite for restoring antique furniture. Its strength may not compare to epoxy, but it still provides enough hold for most traditional woodworking projects.

Cyanoacrylate Glue (Superglue)

Cyanoacrylate glue, commonly known as superglue, is a fast-drying adhesive known for its quick bonding.

- Strength Comparison: Superglue is not as strong as PVA or epoxy glue, but it excels in small repairs and delicate projects. Its rapid curing time makes it ideal for situations where speed is critical.

- Applications: Superglue works well for small-scale projects, such as fixing broken pieces or bonding small wooden objects. It’s not ideal for larger projects, where strength and durability are necessary.

Hot Melt Glue

Hot melt glue is widely used in fast-paced work environments where speed is a priority.

- Applications: It’s often used in DIY projects, crafting, and smaller woodworking jobs. Hot melt glue is quick to apply and doesn’t require clamping, making it ideal for rapid work.

- Strength and Durability Overview: Hot melt glue provides a temporary bond that can be strong enough for certain tasks but lacks the long-term strength that other wood glues offer. It’s perfect for short-term projects but not ideal for high-stress applications.

Comparison Table: Types of Wood Glue and Their Strengths

This table provides a side-by-side comparison of the most common types of wood glue, highlighting their unique characteristics, strengths, and ideal applications. By using this table, you can easily decide which type of glue will best suit your woodworking project based on factors like strength, drying time, and resistance to moisture.

| Type of Glue | Strength | Best For | Pros | Cons |

|---|---|---|---|---|

| PVA Glue (Polyvinyl Acetate) | Moderate to strong (suitable for most indoor projects) | Crafts, furniture, indoor woodworking | Easy to use, fast drying, affordable | Not resistant to moisture, weaker bond on oily woods |

| Epoxy Glue | Very strong (stronger than wood itself) | Heavy-duty projects, outdoor furniture, repairs | Superior strength, water and heat resistant, durable | Longer curing time, more complex to apply |

| Polyurethane Glue | Strong (water and moisture resistant) | Bonding wood to metal, stone, and other materials | Expands as it cures, excellent water resistance | Messy, longer curing time, requires clamping pressure |

| Hide Glue | Moderate (weaker than modern adhesives) | Fine woodworking, antique restoration | Reversible bond, ideal for antique furniture | Weaker bond compared to synthetic glues, temperature sensitive |

| Cyanoacrylate Glue (Superglue) | Low to moderate (not ideal for large projects) | Small repairs, quick fixes, delicate projects | Fast-drying, bonds small items quickly | Weak for large joints, can be brittle under stress |

| Hot Melt Glue | Low to moderate (temporary bond) | DIY projects, crafting, temporary fixes | Fast to apply, no clamping needed, easy to use | Less durable, not suitable for long-term use |

How Strong is Wood Glue? Factors Affecting Strength

Several factors impact how strong wood glue bonds. Understanding these factors will help you maximize the strength of your glue joints.

Type of Wood

The type of wood you’re working with plays a crucial role in the strength of the bond.

- Softwoods vs. Hardwoods: Softwoods, such as pine, typically form stronger bonds with wood glue because their fibers are more porous. Hardwoods, like oak and maple, have a denser structure that can make it harder for glue to adhere effectively.

- Specific Wood Types and Their Glue Strength: Different species of wood will yield varying results with glue. Woods with high natural oil content, such as cherry and walnut, may cause glue to bond less effectively, while others like birch and pine provide excellent adhesion.

Surface Preparation

How well you prepare the wood surfaces before applying glue can significantly affect bond strength.

- Importance of Clean Surfaces: Before applying glue, the surfaces of the wood must be clean and free of dirt, oils, or any contaminants. Failure to clean the wood thoroughly can weaken the glue bond and lead to joint failure.

- Sanding and Cleaning: Sanding wood smooth and wiping down the surfaces with a damp cloth will help create a better surface for adhesion. A clean, smooth surface allows the glue to spread evenly and penetrate the wood fibers more effectively.

Clamping Time

Clamping time is essential to ensure the strength of the bond.

- Significance of Proper Clamping: When you clamp the wood pieces together, the pressure helps align them perfectly while the glue dries. If there is too little clamping pressure, the glue will not form a strong bond. Too much pressure can squeeze out the glue, weakening the joint.

- Optimal Clamping Time: Most wood glues require at least 30 minutes to one hour of clamping, depending on the type of adhesive used. After clamping, it’s best to allow the glue to cure fully before subjecting the joint to stress. Full curing time may take several hours or even a day.

Environmental Factors

The environment plays a significant role in how wood glue performs.

- Temperature and Humidity: Both temperature and humidity can impact the drying time and strength of the bond. Extreme heat or cold can slow down the curing process, while high humidity may prevent the glue from bonding properly. It’s essential to use wood glue in an environment with moderate temperature and humidity.

- Water Exposure and Extreme Conditions: Exposure to water can weaken some types of glue. If your project will be exposed to moisture, it’s best to choose a water-resistant adhesive, such as epoxy or polyurethane glue. Extreme temperature changes and UV light can also degrade the bond over time.

Glue Application Method

The way you apply glue is just as important as the glue itself.

- Too Much or Too Little Glue: Applying too much glue can result in an uneven bond, as excess glue may spill out from the joint and weaken the bond. On the other hand, applying too little glue can leave gaps in the joint, making the bond weak. It’s important to use just the right amount of glue to create a strong, reliable bond.

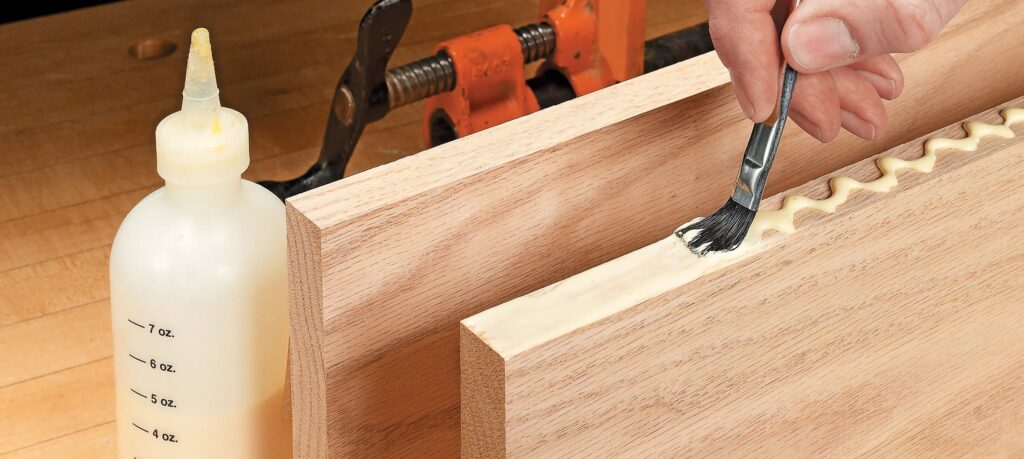

- Best Practices for Application: The key is to apply a thin, even layer of glue across both surfaces being joined. This ensures that the glue covers all the contact points without excess. Using a brush or spreader can help apply an even layer for maximum adhesion.

Strength of Wood Glue vs. Wood Itself

It’s helpful to compare the strength of wood glue to the natural strength of wood to understand the limits and benefits of wood glue.

Tensile Strength Comparison

Tensile strength refers to the maximum amount of force an adhesive can handle before it breaks. When tested, wood glue typically demonstrates a higher tensile strength than the natural tensile strength of wood itself. This means that the wood glue bond often becomes the strongest part of the joint.

Shear Strength

Shear strength refers to how well the glue holds up under forces applied from the side. While wood glue provides excellent shear strength, it’s generally lower than the shear strength of the wood itself. This is why some projects benefit from the added reinforcement of screws or nails, in addition to glue.

Wood Glue Failure

When wood glue fails, the failure usually occurs along the adhesive line, with the wood itself remaining intact. This typically happens if the glue was improperly applied or the joint wasn’t adequately prepared. Recognizing the causes of glue failure helps prevent it in future projects.

Testing Wood Glue Strength

To truly understand how strong wood glue is, it’s helpful to test it yourself or rely on standard testing procedures.

Laboratory Tests vs Real-World Applications

In labs, wood glue is tested under controlled conditions. However, real-world conditions can be unpredictable, and factors like temperature, humidity, and wood type can influence the glue’s performance. While lab tests provide valuable data, practical experience is essential for gauging how the glue will perform in your specific situation.

Common Strength Tests

Common tests to measure wood glue strength include shear tests, tensile tests, and impact resistance tests. These tests measure the glue’s ability to resist different types of forces before failing. Understanding these tests can help you select the best adhesive for your project.

How to Test the Strength of Wood Glue Yourself

You can test the strength of wood glue by performing simple experiments at home. Bond two pieces of wood together with your chosen glue, clamp them in place, and then apply force to the joint to see how much stress it can take before the glue bond breaks.

Best Practices for Maximizing Wood Glue Strength

Maximizing the strength of wood glue requires attention to detail and following proper techniques.

Choosing the Right Glue for the Job

When selecting wood glue, consider the specific needs of your project. For example, if your project involves outdoor furniture, epoxy or polyurethane glue would be a better choice due to their resistance to moisture. If you are working with fine furniture, hide glue might be the best option.

Optimizing Application

The key to a strong bond is applying the glue evenly. Use a brush or a spreader to ensure that both surfaces are fully covered without excess. Properly align the wood pieces before clamping to ensure a uniform bond.

Curing Time and Patience

Allowing the glue to fully cure is crucial for achieving a strong bond. Rushing the process by handling the joint before the glue has fully dried can lead to weak joints that may fail under stress. Always give the glue time to cure according to the manufacturer’s instructions.

Avoiding Common Mistakes

Avoid common mistakes such as over-clamping, which can squeeze out too much glue, or under-clamping, which can prevent the glue from forming a strong bond. It’s also important to avoid rushing the curing process, as this can lead to weak joints.

Comparing Wood Glue Strength to Other Adhesives

Wood glue is just one option among many adhesives available, and it’s useful to understand how it compares to other options.

Wood Glue vs. Superglue

Superglue is fast-drying and ideal for small repairs, but it doesn’t have the holding power of wood glue. For larger projects, wood glue is the superior option as it provides better strength and durability.

Wood Glue vs. Screws and Nails

While screws and nails can create strong mechanical joints, wood glue offers additional strength. When used together, wood glue and fasteners provide the ultimate bond for woodworking projects, with the glue strengthening the joint and providing more long-term stability.

Wood Glue vs. Construction Adhesive

Construction adhesives are stronger than most wood glues, especially when bonding materials other than wood. However, wood glue excels in its ability to bond wood pieces together seamlessly. In woodworking, wood glue remains the best option for wood-to-wood joints.

How to Choose the Right Wood Glue for Your Project

Choosing the best wood glue for your project depends on various factors such as the wood type, project size, and intended use.

- Factors to Consider: Think about the project’s scale, the wood’s properties, and whether the final product will be exposed to moisture or extreme temperatures. These factors will help guide your glue selection.

- Brand Recommendations: Trusted brands like Titebond, Gorilla Glue, and Elmer’s are well-known for producing high-quality wood adhesives suitable for various types of woodworking projects.

Wrapping Up

When it comes to wood glue, knowing its strength and the factors that affect it is critical to ensuring the success of your woodworking projects. Each type of glue has its strengths and ideal uses, so choose carefully. The more informed you are about how strong wood glue can be, the better your chances of creating durable, long-lasting bonds. By following best practices and selecting the right adhesive for each project, you can ensure your joints are as strong as possible.