What Makes Birch Plywood Special?

Birch plywood has become a go-to material for designers, builders, and DIY enthusiasts worldwide. Whether for furniture, cabinetry, or flooring, it’s highly valued for its unique combination of beauty, strength, and workability. This material is an excellent choice for projects requiring durability without compromising on aesthetics. Its smooth, light-colored surface and tight, even grain make birch plywood an attractive and functional option for a wide range of applications.

The versatility of birch plywood is one of its standout features. Whether you’re creating fine furniture or constructing large industrial panels, birch plywood proves itself as a reliable material. It’s a workhorse in various fields, yet its refined look makes it suitable for high-end design projects. But what exactly makes birch plywood so special? Let’s take a deeper look into its properties and discover why it has remained a top choice for professionals across different industries.

The Science Behind Birch Plywood: What Is It Made Of?

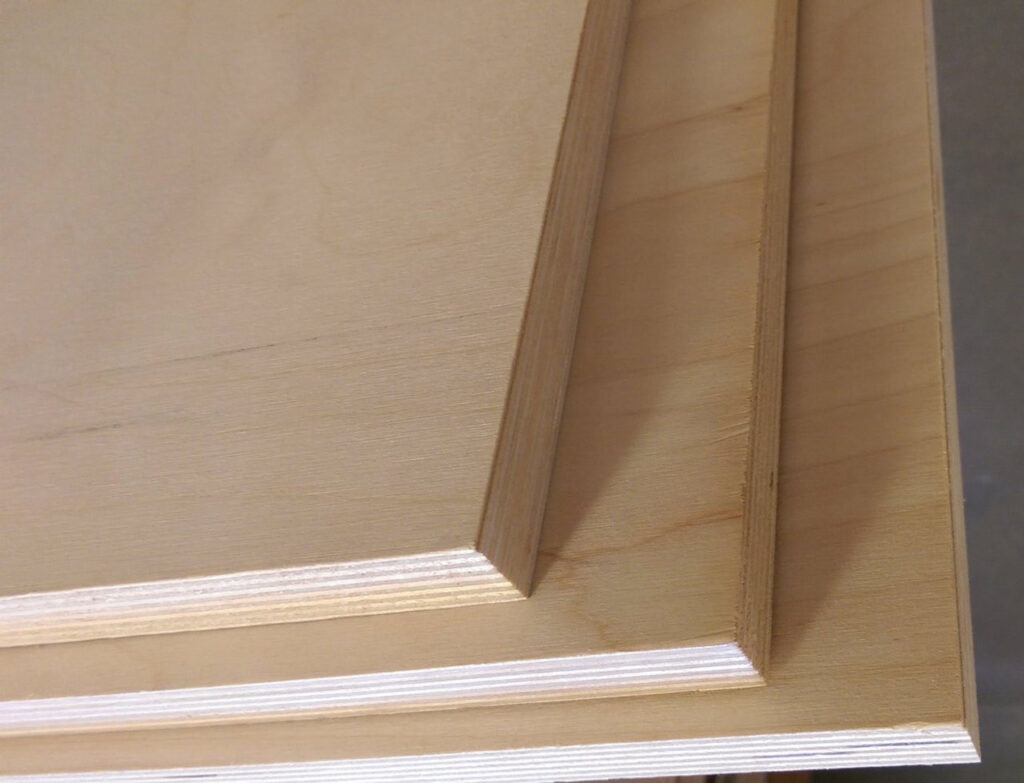

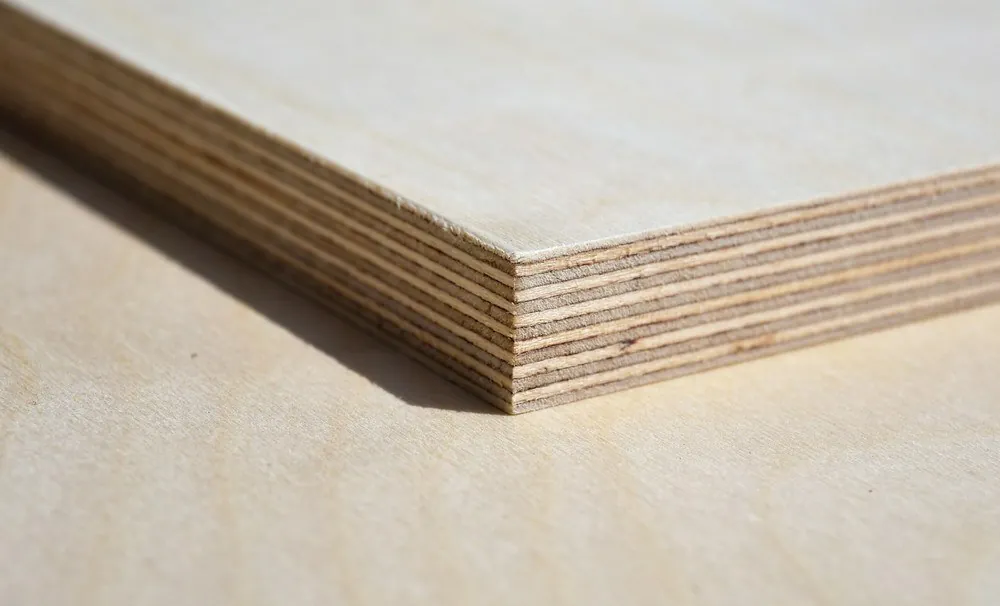

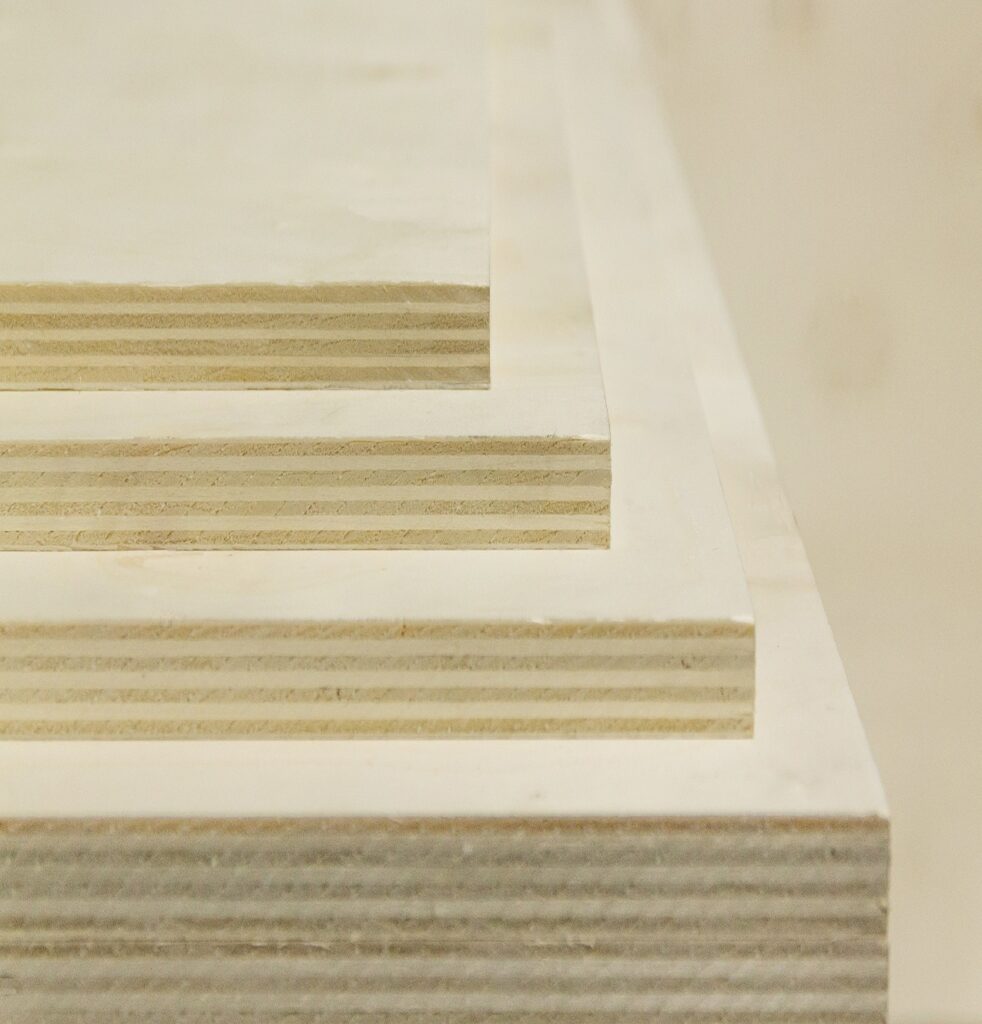

To truly appreciate the value of birch plywood, we need to understand its composition and manufacturing process. Birch plywood is crafted by stacking thin layers of birch wood, also called veneers, together. These layers are then bonded with adhesive under high pressure. The way these veneers are stacked is key to the material’s strength and stability. In a typical construction, the grain of each veneer layer runs perpendicular to the one beneath it. This cross-grain design significantly boosts the plywood’s resistance to warping, cracking, and shrinking.

Layers of Birch Wood: How Is Birch Plywood Made?

The process starts with selecting high-quality birch logs, often sourced from cold, northern regions. These logs are then peeled or sliced into thin sheets, which are the veneers that make up the plywood. The quality of the veneer determines the overall look and performance of the plywood, and birch is one of the finest hardwoods available.

Each veneer layer is coated with a strong adhesive, typically a phenolic resin, that bonds the wood layers together. The adhesive must be able to withstand high temperatures and humidity, ensuring that the finished plywood is durable and can be used in different environments. After being bonded, the sheets are pressed together under immense pressure, which not only makes them more compact but also improves the overall strength and stability of the plywood.

Once the plywood is dried, it is sanded to a smooth finish, ready for a variety of uses. The final product is strong, stable, and surprisingly lightweight, making it easy to handle while providing superior performance.

Unique Properties of Birch Wood Compared to Other Types

What sets birch plywood apart from other types of plywood, such as oak or maple, is its unique combination of properties. Birch wood has a dense and uniform grain structure that gives it a smooth, even texture. Unlike oak, which can have visible knots or imperfections, birch plywood maintains a fine, consistent surface that looks polished and elegant.

Another important feature of birch plywood is its high density, which contributes to its remarkable strength. Birch plywood is also more stable than some other hardwoods because it is less prone to warping and expanding with moisture. In fact, birch plywood performs better in varying humidity levels, making it a preferred material for projects where environmental stability is a concern.

Birch plywood’s ability to maintain its shape and form over time makes it a superior choice for demanding applications such as flooring, cabinetry, and furniture construction. It’s also less likely to split or crack under pressure, which ensures that your projects will stand the test of time.

Why Choose Birch Plywood? The Key Benefits Explained

Birch plywood has many benefits that make it a popular choice for both professionals and DIYers. From its strength and durability to its aesthetic appeal, birch plywood offers a wide range of advantages. Here’s a closer look at why birch plywood is such an outstanding material.

Durability and Strength

Birch plywood is renowned for its exceptional strength. The cross-grain design of its layers enhances its structural integrity, making it incredibly strong for its weight. Birch plywood can handle a wide variety of stresses without compromising its form. It resists bending, cracking, or warping, even when subjected to heavy loads. This makes it the ideal material for applications like flooring, furniture making, and cabinetry that demand long-term performance.

Its durability isn’t just about strength; birch plywood also resists everyday wear and tear. From daily foot traffic on floors to the constant opening and closing of cabinet doors, birch plywood can withstand the demands of regular use without showing signs of damage. This long-lasting quality makes it a wise investment for anyone looking to create high-quality, enduring products.

Lightweight Yet Sturdy

Despite its durability, birch plywood is surprisingly lightweight compared to many other types of plywood. This characteristic is particularly important when working on large projects or when materials need to be moved around frequently. For example, building furniture or installing wall panels with birch plywood is much easier than using denser, heavier materials. The lightness of birch plywood allows for easier handling, cutting, and transportation without sacrificing strength.

Being lightweight also means that birch plywood is less likely to put unnecessary strain on structures. Whether you’re creating a complex shelving unit or designing modular pieces of furniture, the reduced weight of birch plywood allows for easier construction and installation, reducing the overall weight load on the structure itself.

Resistance to Warping and Cracking

Wood, in general, is prone to warping or cracking over time due to environmental factors like changes in temperature and humidity. However, birch plywood excels in this area. The cross-lamination process used in its construction makes it more stable than solid wood or other types of plywood. As the layers are bonded in a perpendicular arrangement, birch plywood resists expansion or contraction with temperature and humidity changes.

This characteristic is especially beneficial when using birch plywood in environments where moisture levels fluctuate, such as kitchens, bathrooms, or basements. Birch plywood maintains its structural integrity, ensuring that your projects remain in top condition even in challenging conditions. Its dimensional stability makes it an excellent choice for projects that need to withstand the test of time.

Aesthetic Appeal

The light color of birch plywood, coupled with its fine grain, gives it an elegant and clean appearance. Unlike other woods with more visible grain patterns, birch plywood has a subtle texture that can be easily stained or painted to suit any design preference. This natural beauty makes it perfect for projects where the appearance of the material plays a significant role.

Birch plywood provides a high-quality base for a wide range of finishes, from clear coats that highlight the natural wood grain to bold paints that completely transform its look. Its smooth, consistent surface means that it can be used for a variety of design styles, from rustic to contemporary.

Birch Plywood vs Other Plywoods: Is It the Best Choice?

When selecting plywood for a specific project, it’s important to compare different options. While birch plywood is an excellent choice, it’s not the only option available. How does it stack up against other popular types of plywood, such as poplar, oak, and maple? Let’s take a look at how birch plywood compares.

Comparing Birch Plywood to Poplar, Oak, and Maple Plywood

- Poplar Plywood: Poplar plywood is a softer wood compared to birch, which means it’s lighter and easier to work with. However, it lacks the strength and durability of birch plywood. Poplar plywood is more prone to dents, scratches, and wear over time. For projects requiring durability, birch plywood is the better choice.

- Oak Plywood: Oak plywood is a hardwood known for its strength and rich grain. However, oak is generally more expensive than birch plywood. While oak offers an aesthetic appeal with its prominent grain patterns, birch plywood provides a more consistent and smooth finish at a more affordable price point. For those seeking value without sacrificing quality, birch plywood is a top contender.

- Maple Plywood: Maple plywood shares many of the same characteristics as birch plywood. Both have a fine grain and offer excellent strength. However, birch plywood is typically more stable and resistant to warping and cracking, making it a more reliable choice for long-term durability. Additionally, birch plywood is often more cost-effective than maple, making it a budget-friendly option for many applications.

| Aspect | Birch Plywood | Other Plywood Types (e.g., Poplar, Oak, Maple) |

| Durability & Strength | Strong, durable, and resistant to warping and cracking. | Varies by type; poplar is softer and less durable, oak is strong but heavy. |

| Weight | Lightweight yet sturdy. | Poplar is light; oak is much heavier than birch. |

| Aesthetic Appeal | Smooth texture, light color, fine grain, takes stain well. | Oak has a prominent grain, maple is smooth but slightly darker than birch. |

| Cost | Moderate price range, cost-effective for long-term use. | Poplar is usually cheaper, while oak is generally more expensive. |

| Moisture Resistance | Not waterproof, but can be treated for moisture resistance. | Oak is more moisture-resistant naturally; poplar and maple are less so. |

| Ease of Staining | Takes stain beautifully, lighter color enhances finish. | Maple may show streaks; oak can absorb stain unevenly, giving a rustic look. |

| Environmental Impact | Renewable resource, especially from sustainable sources. | Similar in sustainability, but oak can be less eco-friendly due to slower growth. |

| Applications | Furniture, cabinetry, interior design, commercial uses. | Oak is best for heavy-duty applications, poplar for lightweight projects. |

| Screw Holding Ability | Strong screw holding, does not split easily. | Oak has excellent screw-holding strength, poplar weaker than birch. |

| Shape Retention | Stable under changes in temperature or humidity. | Oak and maple are more stable in high humidity, poplar is less stable. |

Cost-Effectiveness and Availability

Birch plywood is not only highly durable and aesthetically pleasing but also reasonably priced compared to other high-quality plywood options. It is often more affordable than oak or maple plywood, which makes it an ideal choice for projects that require strength and beauty without breaking the bank.

Moreover, birch plywood is widely available, making it easy to source in various grades, sizes, and finishes. Whether you’re purchasing a few sheets for a small DIY project or ordering bulk quantities for a large commercial build, birch plywood is readily accessible.

Applications of Birch Plywood: Where Does It Shine?

Birch plywood’s versatility makes it suitable for a wide range of applications. Its strength, workability, and aesthetic appeal make it a preferred choice for both residential and commercial projects. Here are just a few examples of where birch plywood excels.

Furniture Making

Birch plywood is a favorite among furniture makers due to its durability, smooth finish, and attractive appearance. It’s commonly used in the construction of tables, chairs, bookshelves, cabinets, and more. Its strength ensures that the furniture can support weight and resist wear, while its smooth surface is perfect for both staining and painting.

For DIYers, birch plywood offers endless possibilities for creating custom pieces of furniture. Whether you’re crafting a modern bookshelf or building a custom dining table, birch plywood is a versatile and reliable material.

Interior Design

Birch plywood is widely used in interior design for both residential and commercial spaces. It can be used for wall panels, ceiling designs, flooring, and even custom cabinetry. The clean, smooth surface of birch plywood enhances the overall aesthetic of a room, while its strength ensures that it stands up to everyday use.

For more contemporary designs, birch plywood provides a minimalist look that complements modern decor. It can also be used in traditional settings, offering a warm, natural touch that blends seamlessly with other materials.

DIY Projects and Crafts

For DIY enthusiasts, birch plywood is a go-to material due to its workability and natural beauty. Its smooth surface makes it easy to cut, shape, and finish, making it ideal for crafting. Whether you’re building a small decorative item, such as a picture frame or a toy, or tackling a larger project, such as a custom bookshelf or bench, birch plywood is a reliable choice.

The material’s light color also means it takes stains and paints beautifully, allowing you to create a wide range of finishes. Birch plywood is also a popular choice for creating intricate laser-cut designs, making it a favorite among crafters and hobbyists alike.

Commercial Uses

In commercial settings, birch plywood is commonly used for applications like shopfitting, display units, and cabinetry. Its strength and aesthetic appeal make it a preferred material for creating high-end commercial fixtures and displays. Whether it’s for a retail environment or an office space, birch plywood adds both functionality and style.

Due to its durability, birch plywood is also used in applications like flooring and wall coverings in commercial spaces that experience heavy foot traffic. It’s an ideal material for environments where both form and function are important.

Is Birch Good for Cabinets? Why You Should Consider It for Your Next Project

When considering materials for cabinetry, birch plywood stands out as one of the top choices. Its combination of durability, strength, and aesthetic appeal makes it perfect for both modern and traditional cabinet designs. Let’s take a closer look at why birch plywood is an ideal option for creating beautiful and long-lasting cabinets.

Durability and Strength: Why Birch Plywood Is Perfect for Cabinets

Cabinets undergo a lot of use. They are opened and closed repeatedly, often bearing the weight of items inside. For this reason, it’s crucial to choose a material that can withstand constant stress and wear. Birch plywood is incredibly strong due to its cross-grain construction, which provides excellent resistance to bending and twisting. This makes birch plywood an excellent choice for cabinet doors, drawers, and shelves.

Additionally, birch plywood is less prone to warping compared to other materials, especially when exposed to humidity and temperature changes. In areas like kitchens and bathrooms, where moisture levels fluctuate, birch plywood remains stable and performs well, even in challenging conditions.

Aesthetic Appeal: How Birch Plywood Enhances Your Cabinetry Design

One of the standout features of birch plywood is its smooth, uniform texture. The light color of birch adds a soft, natural touch to any room. Its fine grain pattern complements both contemporary and classic design styles, making it a versatile option for all types of cabinetry.

Birch plywood can be stained or painted to achieve various looks. Its light base color allows for the full range of stains, from deep, rich hues to lighter shades, without interfering with the overall finish. Whether you’re going for a modern, sleek look or a more traditional wood finish, birch plywood adapts well to different design preferences.

For those who prefer an unfinished look, birch plywood has a clean, minimalist appearance that fits seamlessly into contemporary interior designs. Its light, neutral color also pairs well with other materials, such as glass, metal, or stone, to create a cohesive and balanced aesthetic.

Technical Characteristics: Why Birch Plywood Is Ideal for Cabinet Construction

Birch plywood’s technical properties make it particularly suited for cabinetry. It has a high shear strength, which means it can withstand the forces applied when opening and closing doors and drawers. This feature is crucial for the longevity of cabinets, ensuring they maintain their shape and function over time.

Additionally, birch plywood holds screws and nails exceptionally well. This characteristic allows for secure construction, so your cabinets will stay sturdy even with frequent use. Birch plywood also resists delamination, meaning the individual layers remain intact even under pressure, which ensures your cabinets will not fall apart over time.

Is Birch Plywood Waterproof? How to Protect It from Water Damage

While birch plywood is known for its durability and resistance to warping, it is not entirely waterproof. However, its moisture resistance can be enhanced with proper treatment and care. Let’s take a look at how birch plywood behaves when exposed to moisture and how you can protect it to ensure long-lasting performance.

Birch Plywood and Moisture: What You Need to Know

When exposed to water or high humidity for prolonged periods, birch plywood can absorb moisture, which may cause it to swell or warp. However, birch plywood is more resistant to moisture than many other types of plywood, making it suitable for environments where some level of moisture is present, such as kitchens, bathrooms, and basements.

If you’re using birch plywood in a high-moisture area, such as a bathroom or kitchen, it’s essential to take steps to protect it. Applying a protective finish, such as a waterproof coating, can significantly improve its resistance to water. Without proper treatment, birch plywood is best suited for dry areas where moisture exposure is minimal.

Protective Coatings for Birch Plywood

To enhance the moisture resistance of birch plywood, a variety of protective coatings can be used. Clear polyurethane varnish, for example, creates a waterproof barrier that helps prevent moisture from seeping into the wood. Polyurethane finishes are durable and easy to apply, providing a tough, water-resistant layer that preserves the integrity of the plywood.

For a more natural, oil-based finish, tung oil or Danish oil can be applied. These oils penetrate the wood, providing moisture protection while highlighting the wood’s natural beauty. Be sure to apply multiple coats of oil and allow adequate drying time to achieve the best results.

In addition to varnish and oils, specialized water-resistant wood sealants can be used to protect birch plywood from water damage. These products form a protective layer on the surface that prevents moisture from being absorbed into the wood. If you’re working on projects like kitchen cabinets or bathroom vanities, using a water-resistant finish is highly recommended.

Using Birch Plywood in Wet Conditions

Even though birch plywood is moisture-resistant, it’s important to note that it isn’t designed for direct exposure to water. In areas with high humidity or direct water contact, such as shower areas, it’s best to use plywood that’s specifically treated for wet environments. If you still want to use birch plywood in these spaces, be sure to protect it with a high-quality water-resistant coating and keep the material dry whenever possible.

Staining Birch Plywood: Tips and Techniques for a Stunning Finish

Staining birch plywood can be a bit tricky, as its light color and fine grain can sometimes result in uneven coloration. However, with the right techniques and products, you can achieve a beautiful, professional-looking finish. Let’s explore how to stain birch plywood and get the best results.

Why Staining Birch Plywood Can Be Challenging

Birch plywood’s light, even color can make it harder to achieve a consistent stain finish. The wood tends to absorb stains unevenly, especially if the stain is too thick or applied too quickly. Additionally, the fine grain of birch plywood can sometimes result in blotchy areas, making it challenging to get a uniform tone.

To achieve a smooth and even stain on birch plywood, it’s essential to take your time and follow the right steps. Pre-conditioning the wood can help ensure that the stain is absorbed more evenly, resulting in a more consistent finish.

Tips for Staining Birch Plywood

- Pre-sand the surface: Start by sanding the plywood to ensure a smooth and even surface. Use fine-grit sandpaper to avoid damaging the wood or leaving noticeable scratches.

- Apply a wood conditioner: To prevent blotches and uneven staining, apply a wood conditioner before staining. This product helps the wood absorb the stain more evenly, resulting in a uniform finish.

- Choose the right stain: When selecting a stain for birch plywood, choose a product designed for light-colored woods. Gel stains or oil-based stains work well with birch plywood, providing deep, rich color without streaks.

- Test the stain: Before applying the stain to the entire surface, test it on a small, inconspicuous area of the plywood. This will give you an idea of how the wood will react to the stain and help you adjust the application if needed.

- Apply the stain evenly: Use a brush, rag, or sponge to apply the stain in long, even strokes. Work in small sections and wipe away any excess stain before it dries to prevent streaks or blotches.

Creating a Beautiful Finish

Once the stain has dried, you can apply a clear protective finish to preserve the color and add durability. Polyurethane, lacquer, or varnish are all excellent options for finishing birch plywood. A clear finish will help seal the wood, protect it from scratches, and provide a glossy or matte sheen depending on your preference.

If you prefer a more natural look, you can opt for a wax finish. Wax enhances the beauty of the wood while providing a softer, more subtle sheen. Keep in mind that wax finishes may require periodic reapplication to maintain their protective qualities.

How to Work with Birch Plywood: Tips and Techniques

When working with birch plywood, it’s important to use the right tools and techniques to ensure a smooth, professional result. Here are some essential tips for cutting, sanding, and finishing birch plywood.

Cutting Birch Plywood

Birch plywood is relatively easy to cut, but it requires a sharp saw blade to avoid splintering the edges. A circular saw with a fine-tooth blade or a table saw with a carbide-tipped blade is ideal for cutting birch plywood. Always measure and mark your cuts carefully to ensure accuracy.

To reduce the risk of splintering, place masking tape along the cut line before sawing. This will help prevent the edges from fraying and ensure a cleaner cut. Additionally, always cut with the finished side facing down to minimize visible imperfections.

Sanding Birch Plywood

After cutting, sanding birch plywood is necessary to smooth the surface and prepare it for staining or finishing. Start with medium-grit sandpaper to remove any rough spots, then finish with fine-grit sandpaper for a smooth, polished surface.

Be sure to sand along the grain to avoid scratches and ensure an even finish. If you’re applying a stain or finish, take extra care to sand evenly, as any uneven areas can result in blotchy stains or finishes.

Finishing Birch Plywood

Once the surface is smooth and clean, it’s time to apply the finish. Whether you’re using paint, stain, or a clear protective coating, make sure to apply the finish in thin, even layers. Allow each layer to dry completely before applying additional coats.

For the best results, use a high-quality brush or sprayer to apply the finish. A sprayer provides a smooth, even coat and is especially useful for larger surfaces, such as cabinetry or furniture.

Sustainability of Birch Plywood: A Green Choice for the Future

In today’s environmentally conscious world, sustainability plays a crucial role in material selection. Birch plywood is considered one of the more eco-friendly wood products on the market. As consumers and industries shift towards greener choices, understanding the sustainability of birch plywood is becoming increasingly important.

Environmentally-Friendly Sourcing and Production Methods

Birch trees are native to regions with cold climates, particularly in Europe, Russia, and North America. They are abundant in forests that are carefully managed to ensure a healthy and renewable supply of timber. The production of birch plywood relies on a sustainable harvesting process that focuses on responsible forest management practices. Reputable manufacturers source their birch wood from certified forests, ensuring that the wood is harvested in a way that does not harm the environment.

Additionally, birch trees grow relatively quickly compared to other hardwood species, which makes birch a renewable resource. This rapid growth rate ensures that birch forests are not depleted, and that the timber industry can continue to produce birch plywood without causing long-term ecological damage.

Birch Wood as a Renewable Resource

Birch wood is a renewable resource, meaning it can be replenished over time. Unlike some hardwoods that take decades or even centuries to mature, birch trees reach full maturity in a relatively short period — usually around 20-30 years. This rapid growth makes birch an attractive option for sustainable wood products. By choosing birch plywood, you are supporting the use of a renewable resource, which helps reduce the demand for slow-growing, less sustainable timber species.

Moreover, birch trees help maintain ecological balance by absorbing carbon dioxide and releasing oxygen into the atmosphere. This contributes to reducing the carbon footprint, making birch wood not just a renewable resource but also an environmentally beneficial one.

Eco-Certifications to Look For

When purchasing birch plywood, look for eco-certifications that ensure the material was sourced responsibly. Forest Stewardship Council (FSC) certification is one of the most recognized and trusted certifications in the woodworking industry. FSC-certified birch plywood comes from forests that meet rigorous environmental, social, and economic standards.

Other certifications to watch for include the Programme for the Endorsement of Forest Certification (PEFC) and the Sustainable Forestry Initiative (SFI). These certifications guarantee that the birch plywood is sourced from sustainable forests, making it a more eco-friendly choice compared to products made from non-certified wood.

Finishing Birch Plywood: Achieving a Smooth and Long-Lasting Surface

A well-finished surface is key to ensuring that your birch plywood projects look great and stand the test of time. Whether you’re building furniture, cabinetry, or other woodworking projects, taking the time to finish your plywood properly will make a big difference in its appearance and durability.

Preparing the Surface: The Right Steps for a Smooth Finish

Before applying any finish to birch plywood, it’s essential to properly prepare the surface. This involves sanding, dusting, and priming to ensure that the finish adheres well and creates a smooth, even coat.

Start by sanding the surface of the plywood with medium-grit sandpaper (around 120-grit) to remove any rough spots or imperfections. Once the plywood is smooth, switch to fine-grit sandpaper (around 220-grit) to further smooth out the surface. After sanding, use a tack cloth or a vacuum to remove all dust and debris, as dust particles can mar the final finish.

If you’re applying a stain or paint, it’s also a good idea to apply a coat of primer before the finish. The primer helps seal the wood and provides a better base for the paint or stain, ensuring better adhesion and a more uniform finish.

Types of Finishes: Choosing the Best Option for Your Project

Birch plywood can be finished in a variety of ways, depending on the desired look and the type of project you’re working on. Below are some common finishes to consider:

- Clear Coatings (Polyurethane, Varnish, Lacquer): These finishes are ideal for showcasing the natural beauty of the birch plywood while providing a durable protective layer. Polyurethane and varnish offer high resistance to wear and moisture, making them great for furniture or cabinetry that will be frequently used. Lacquer provides a smooth, glossy finish, often used for a more high-end appearance.

- Oil Finishes (Tung Oil, Linseed Oil): Oil finishes penetrate the wood, highlighting the natural grain and adding a subtle sheen. Tung oil and linseed oil are popular choices because they offer protection while preserving the wood’s natural texture and feel. Oil finishes are particularly well-suited for projects where a natural, hand-crafted look is desired.

- Wax: Wax finishes provide a soft, low-sheen surface that is easy to maintain. They are best for pieces that are not exposed to heavy use or moisture. Wax can give birch plywood a smooth, velvety finish that feels pleasant to the touch.

- Stains: If you want to change the color of your birch plywood, stains are an excellent option. Birch absorbs stain evenly when properly prepped, allowing you to create a wide range of colors, from light honey tones to darker shades like walnut or mahogany. For the best results, apply a wood conditioner before staining to ensure an even color.

How to Extend the Life of Your Finished Birch Plywood

Once you’ve applied your finish, it’s important to take steps to maintain the longevity of your birch plywood. Regular cleaning is essential to prevent dust and dirt buildup, which can damage the finish over time. Use a soft cloth and mild cleaner to wipe down the surface, avoiding harsh chemicals that can strip the finish.

For furniture and cabinetry, periodically check for signs of wear and reapply the finish as needed. A fresh coat of polyurethane or oil can help rejuvenate the surface and restore its protective properties. Additionally, if your plywood is exposed to moisture, make sure to inspect the edges and seams for any signs of water damage, and apply additional protective coatings to prevent further harm.

The Costs of Birch Plywood: Understanding the Price Range

When considering birch plywood for your project, cost is an important factor to take into account. While birch plywood is generally more expensive than other types of plywood, its superior quality, durability, and aesthetic appeal often make it worth the investment.

Factors That Affect the Cost of Birch Plywood

Several factors can influence the price of birch plywood, including thickness, grade, and finish. The thicker the plywood, the more it will cost. Additionally, higher-grade birch plywood, which has fewer knots and defects, will generally be more expensive than lower-grade options.

Finishes and treatments also play a role in the price. Pre-finished birch plywood, which comes with a protective coating, will typically be more expensive than unfinished plywood. However, purchasing pre-finished plywood can save you time and effort if you plan to use the material in projects where a smooth, protective surface is needed.

Is Birch Plywood Cost-Effective in the Long Run?

Although birch plywood may have a higher upfront cost compared to other materials, it often proves to be cost-effective in the long run. Its durability and resistance to wear and tear mean that it will last longer and require fewer repairs or replacements over time. For furniture and cabinetry projects, investing in high-quality birch plywood can result in pieces that maintain their appearance and function for years.

Additionally, because birch plywood holds screws and nails well and is easy to work with, the construction process is often faster and more efficient, potentially saving you money in labor costs.

Comparing Prices Across Suppliers

The price of birch plywood can vary depending on the supplier, location, and specific type of plywood. It’s a good idea to compare prices from different suppliers and check for any bulk discounts if you need a large quantity of plywood. Keep in mind that prices may also vary based on the thickness, grade, and finish, so be sure to factor in these variables when calculating your total cost.

How to Care for and Maintain Birch Plywood for Longevity

Proper care and maintenance are key to ensuring that your birch plywood products last for many years. Whether you’re working with birch plywood furniture, cabinetry, or flooring, taking simple steps to protect and maintain the material can greatly extend its life. Below are some essential tips to keep your birch plywood looking great and functioning well.

Protective Finishes and Coatings: Keeping Your Birch Plywood Safe

Applying protective finishes and coatings is one of the most effective ways to protect birch plywood from damage. Without a protective coating, the surface of the plywood is more susceptible to moisture, dirt, stains, and physical wear. Clear finishes like polyurethane or lacquer are excellent options for protecting birch plywood from moisture and scratches. If you choose an oil-based finish, like tung oil or linseed oil, it will offer deep protection while enhancing the natural beauty of the wood.

For projects exposed to high traffic or potential moisture, such as kitchen countertops or bathroom vanities, ensure that the finish you apply is waterproof or water-resistant. Specialized products like marine varnish or epoxy coatings can provide added protection against moisture and heavy wear.

Preventing Damage from Moisture or Temperature Changes

While birch plywood is relatively resistant to moisture compared to other wood products, it is not immune to water damage. Exposure to excess moisture or sudden temperature changes can cause the wood to expand, contract, or warp. To protect your birch plywood from these conditions, it’s essential to maintain stable indoor humidity and temperature levels.

In humid environments, such as bathrooms or kitchens, be sure to seal the edges of the plywood and apply a high-quality finish to prevent moisture from seeping into the wood. Additionally, be mindful of areas where condensation may occur, such as near windows or doors. Use dehumidifiers in rooms with high humidity to maintain optimal conditions and protect the plywood.

Temperature fluctuations can also affect birch plywood. When exposed to extreme heat or cold, the wood may contract or expand, causing stress on the material. It’s important to avoid placing birch plywood items in areas with fluctuating temperatures, such as near radiators, heaters, or air conditioning units. By maintaining a consistent environment, you’ll help the plywood maintain its shape and integrity.

Regular Cleaning and Upkeep Tips

Routine cleaning is an essential part of maintaining birch plywood. Dirt, dust, and debris can accumulate over time and cause scratches or other damage if not removed regularly. To clean birch plywood, start by using a soft cloth or microfiber cloth to dust the surface. Avoid using harsh chemicals or abrasive cleaning products that can damage the finish. If the plywood requires deeper cleaning, use a mild soap solution and a damp cloth, ensuring that the surface is dried immediately afterward.

For furniture, cabinetry, or flooring made from birch plywood, consider placing protective pads under heavy items to avoid scratches or dents. Additionally, avoid placing hot or wet items directly on the surface to prevent moisture damage or heat marks. For tables and countertops, using a placemat or coaster can help protect the plywood from potential damage caused by spills or heat.

Repairing Scratches and Damage

Even with proper care, it’s possible for birch plywood to develop minor scratches, dents, or other imperfections. Fortunately, repairing minor damage is usually straightforward. For small scratches, use a touch-up marker or wood filler in a color that matches the plywood. After applying the filler, gently sand the area and apply a coat of finish to restore the surface.

If you encounter larger dents or damage, you may need to replace the affected section of plywood. This can be done by cutting out the damaged area and replacing it with a new piece of birch plywood. Ensure that the new piece matches the surrounding plywood in terms of thickness and color.

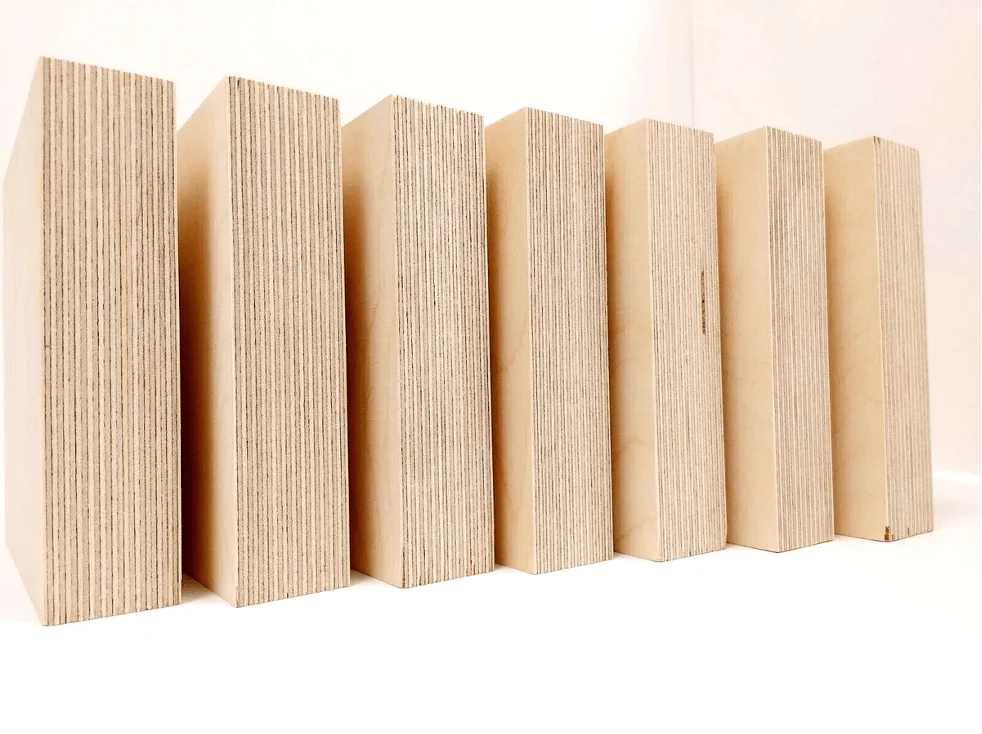

Baltic Birch Plywood: The Superior Choice for Strength and Aesthetics

If you’re looking for a premium option when it comes to birch plywood, Baltic birch plywood is considered one of the highest quality choices available. Originating from the northern regions of Europe, Baltic birch is prized for its exceptional strength, stability, and aesthetic appeal.

What is Baltic Birch Plywood?

Baltic birch plywood is made from high-quality birch trees found in the Baltic region, particularly in countries such as Russia, Finland, and Estonia. Unlike standard birch plywood, which typically has a layered construction with alternating wood species, Baltic birch plywood is made from 100% birch veneers throughout. This creates a consistent structure with superior durability and strength.

Baltic birch plywood is characterized by its dense core and fine grain. It is often considered the premium choice for woodworking projects that require a high level of strength and aesthetic appeal. The layers of Baltic birch plywood are bonded with high-quality adhesives, ensuring stability and resistance to warping or delamination.

Advantages of Baltic Birch Plywood

- Strength and Durability: The uniform construction of Baltic birch plywood makes it stronger and more stable than standard birch plywood. It can support heavy loads and resist damage from impacts or stresses, making it ideal for furniture, cabinetry, and structural applications.

- Consistency: One of the key advantages of Baltic birch plywood is its consistent quality. Since it is made entirely from birch veneers, the material is free from imperfections such as knots or voids, which can sometimes be present in other types of plywood. This makes it a top choice for projects where uniformity is essential.

- Aesthetic Appeal: Baltic birch plywood has a beautiful, smooth finish that showcases the natural beauty of the wood. Its fine, even grain pattern gives it a high-end look, and it stains or finishes evenly without blotches. It’s often used for furniture, cabinetry, and interior design where aesthetics are a top priority.

- Versatility: Baltic birch plywood is versatile and can be used for a wide range of applications. It is commonly used in high-end furniture production, commercial cabinetry, and even musical instruments. Its durability and aesthetic appeal make it an ideal choice for both functional and decorative pieces.

Applications of Baltic Birch Plywood

Baltic birch plywood excels in many applications. Some of the most common uses include:

- Furniture: Whether you’re building chairs, tables, or bookshelves, Baltic birch plywood provides the strength and beauty needed for high-quality furniture pieces.

- Cabinetry: The uniform structure of Baltic birch plywood makes it ideal for cabinetry. It can be used for cabinet doors, shelves, and drawer boxes.

- Commercial Uses: Baltic birch plywood is often used in commercial applications, such as store displays, kiosks, and interior partitions, due to its superior strength and attractive appearance.

- Musical Instruments: The high quality and strength of Baltic birch make it a popular choice for musical instrument construction, particularly for drum shells.

Ideal Projects for Baltic Birch Plywood

Baltic birch is ideal for projects where you need both strength and a beautiful finish. It is particularly well-suited for projects such as:

- Custom Furniture: Because of its uniformity and fine grain, Baltic birch plywood is a preferred material for custom furniture. Whether you’re creating a modern bookshelf or a classic dining table, Baltic birch offers both durability and aesthetic beauty.

- High-End Cabinets: For professional-grade cabinetry, Baltic birch plywood provides superior strength, stability, and smoothness. It can be used for cabinet boxes, doors, and drawer fronts, making it a premium choice for luxury kitchen and bathroom designs.

- Crafts and DIY Projects: Whether you’re building small-scale models or intricate craft projects, Baltic birch plywood is easy to work with and holds up well over time, making it a great choice for DIYers.

Does Birch Stain Well? How to Get the Best Results with Staining

Birch plywood can be a bit tricky when it comes to staining. While its light color provides a great base for stains, achieving an even, rich finish requires some preparation and careful technique. Let’s look at the challenges and tips for staining birch plywood.

Why Staining Birch Plywood Can Be Challenging

Birch plywood is a light-colored wood, which means it can absorb stain unevenly if not properly prepped. The fine grain of birch often results in blotches or streaks when stain is applied. Additionally, because of its pale hue, some stains may appear lighter or more uneven than they would on darker hardwoods.

To get the best results, it’s essential to properly condition the wood before staining, as this helps prevent blotchiness. Proper sanding, using the right stain, and applying the stain correctly will all contribute to a more uniform and attractive finish.

Tips for Staining Birch Plywood

- Pre-sand the Surface: Sand the plywood with fine-grit sandpaper (220-grit or finer) to remove any rough spots and ensure a smooth surface. Birch is softwood, so be cautious not to over-sand, which can damage the veneer.

- Use a Wood Conditioner: Before applying stain, use a wood conditioner to seal the wood and promote even absorption. This is especially important for birch plywood, as it can prevent blotchy, uneven staining.

- Apply Stain in Thin Layers: Apply the stain in thin, even layers, working with the grain. If you’re looking for a darker color, build up the stain in multiple coats, allowing each coat to dry before applying the next.

- Test on Scrap Pieces: Before applying the stain to the entire surface, test it on a scrap piece of birch plywood. This will help you gauge how the wood will react to the stain and allow you to make adjustments if needed.

- Wipe Off Excess Stain: After applying the stain, wipe off any excess with a clean cloth. This helps prevent uneven coloring and ensures a smooth, uniform finish.

Is Birch Plywood Waterproof? Understanding Its Water Resistance and How to Protect It

Birch plywood is a durable and versatile material, but it’s important to understand its limitations when it comes to exposure to moisture. While birch plywood has some natural resistance to moisture, it is not fully waterproof. This makes it suitable for a range of applications, but if exposed to water for extended periods, it can swell, warp, or degrade over time. However, with the right protective measures, birch plywood can be used in environments with high humidity or moisture.

How Birch Plywood Responds to Moisture

Birch plywood is constructed with layers of wood veneers that are bonded together with adhesive. This layered structure can offer some resistance to moisture, but the plywood itself is not inherently waterproof. The adhesive used to bond the layers of veneer can weaken if exposed to water over time, causing the layers to separate. Additionally, the wood fibers in birch plywood can absorb moisture, leading to swelling, warping, or cracking.

That said, birch plywood can handle moderate exposure to moisture, especially in controlled environments. For example, in indoor areas like kitchens or bathrooms, where moisture levels fluctuate but don’t remain consistently high, birch plywood can hold up well if properly sealed and protected.

How to Protect Birch Plywood from Moisture

To make birch plywood more resistant to moisture, there are several options for sealing and protecting the surface. One of the most effective ways to enhance moisture resistance is to apply a protective finish. Depending on the type of project, you can choose from a variety of finishes to help protect the wood from moisture damage.

- Polyurethane Finish: Applying a polyurethane finish, whether oil-based or water-based, can help seal the plywood and create a barrier against moisture. Polyurethane forms a durable coating that prevents water from penetrating the wood, making it ideal for high-moisture areas like kitchens, bathrooms, or outdoor projects.

- Marine Varnish: For projects exposed to high levels of moisture or outdoor environments, marine varnish is an excellent choice. This finish is designed to withstand harsh weather conditions, providing strong protection against moisture, UV rays, and temperature fluctuations.

- Epoxy Coatings: Epoxy coatings are another effective option for protecting birch plywood in areas where it will be exposed to moisture. Epoxy creates a thick, waterproof barrier that seals the wood and prevents water from entering the grain.

- Oil Finishes: Tung oil or linseed oil can provide a water-resistant finish while enhancing the natural look of birch plywood. While not as waterproof as polyurethane or epoxy, oil finishes penetrate the wood and offer some protection against moisture, making them suitable for low-to-moderate exposure.

Tips for Using Birch Plywood in High-Humidity Areas

If you plan to use birch plywood in a high-humidity area, such as a bathroom or basement, it’s essential to take additional steps to protect the material. First, ensure that the plywood is properly sealed before installation. Pay special attention to the edges and joints, as these areas are most susceptible to moisture infiltration. For outdoor applications, choose high-quality finishes that are designed for extreme conditions.

If your birch plywood project is exposed to a lot of moisture, consider using a more moisture-resistant wood or material in conjunction with birch plywood for added protection. For example, you can use moisture-resistant plywood as a substrate and apply birch plywood on top for aesthetic purposes.

Is Birch Good for Cabinets? Why You Should Consider It for Your Next Project

Birch plywood is a fantastic choice for cabinetry due to its durability, attractive appearance, and versatility. Whether you’re designing custom cabinets for a kitchen, bathroom, or other areas of your home, birch plywood offers a balance of strength, beauty, and practicality.

Durability and Strength: Why Birch is a Top Choice for Cabinets

When it comes to building cabinets, durability is one of the most important factors to consider. Birch plywood has excellent strength and is resistant to damage from impacts, making it ideal for high-traffic areas like kitchens or commercial spaces. The multi-layered structure of birch plywood gives it added stability, ensuring that it holds up well under pressure. In cabinetry, where shelves and drawer boxes are subject to weight, birch plywood can handle the load without sagging or warping.

Moreover, birch plywood has superior screw-holding capabilities, meaning the screws will stay securely in place, even under stress. This is especially important for cabinet construction, as it ensures that the joints remain tight and the cabinet structure is solid over time.

Aesthetic Appeal: The Beauty of Birch for Modern and Classic Interiors

Birch plywood is not only durable, but it also has a smooth, light-colored surface that looks elegant in both modern and traditional interiors. The fine, even grain of birch plywood enhances the natural beauty of the wood, giving it a clean, fresh appearance that complements various design styles.

In modern kitchens and bathrooms, birch plywood can provide a minimalist and sleek look. Its light, neutral tone works well with a range of materials and colors, from bold, contemporary designs to more classic, understated aesthetics. When stained, birch plywood can take on deeper hues, making it suitable for more luxurious cabinet designs as well.

The versatility of birch plywood allows it to fit seamlessly into many different interior design schemes. Whether you’re going for a natural wood finish or a stained effect, birch plywood’s fine grain and smooth texture make it an excellent choice for custom cabinetry.

Technical Characteristics: Strength and Stability for Cabinet Construction

Birch plywood is known for its high strength-to-weight ratio, meaning it’s strong yet lightweight — an essential quality for cabinetry, which requires ease of installation without sacrificing structural integrity. Its stability ensures that cabinets remain square and true, even after years of use.

One of the key technical characteristics of birch plywood is its high shear strength, which means it resists forces that could cause it to bend or deform. This is particularly important for cabinet doors, which are subject to regular opening and closing. The plywood’s stability also reduces the risk of expansion or contraction due to changes in humidity, which can be a problem with lesser-quality plywood.

Another benefit of birch plywood is its ability to maintain form under pressure. Unlike softer woods, which may warp or bow over time, birch plywood holds its shape and structure, ensuring that your cabinets will last for years without significant deterioration.

Final Thoughts: Why Birch Plywood Continues to Be a Top Choice

In summary, birch plywood continues to be a favorite material among professionals and DIY enthusiasts alike for its versatility, durability, and aesthetic appeal. From its excellent strength and resistance to warping, to its smooth, light-colored surface that takes stains beautifully, birch plywood is the perfect choice for a wide variety of projects.

Whether you’re building furniture, cabinetry, flooring, or other woodworking projects, birch plywood offers the perfect combination of beauty and function. With proper care and maintenance, birch plywood can last for decades, making it an investment that pays off in both the short and long term.

If you’re considering birch plywood for your next project, take the time to explore its many benefits, and you’ll be rewarded with a high-quality result that will stand the test of time.