When it comes to plywood, many options are available for different applications, but one type stands out in a variety of industries: lauan plywood. Its unique composition, wide range of uses, and aesthetic appeal make it a popular material for construction, furniture-making, and interior design. If you’ve ever wondered, «What is lauan plywood?» you’re not alone. This detailed guide will answer this question, diving deep into its origin, production process, key characteristics, uses, and much more, so you can fully grasp what makes lauan plywood a crucial material in the market.

Definition of Lauan Plywood

To answer the question, “What is lauan plywood?” it’s important to break it down. Lauan plywood is made from the wood of trees that belong to the Shorea genus, which are primarily found in tropical regions of Southeast Asia, including the Philippines, Indonesia, and Malaysia. The trees from this genus are generally classified as hardwoods, and the plywood produced from their wood is typically light to medium reddish-brown in color with a smooth texture and fine grain.

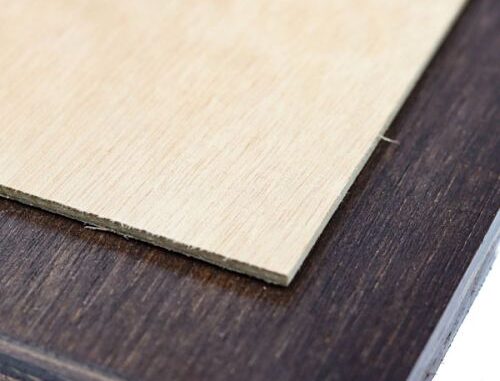

The plywood itself is constructed by bonding thin layers, or veneers, of lauan wood together with adhesives. These layers are laid out in a cross-grain manner, meaning each layer’s grain is oriented perpendicular to the layer beneath it. This arrangement helps to increase the strength and stability of the plywood, reducing the risk of warping or splitting over time.

In addition to its structural benefits, lauan plywood also offers a relatively affordable alternative to other higher-end plywood types like mahogany, while still providing an attractive and durable finish. It’s versatile and often chosen for both its practical and aesthetic qualities.

Overview of Lauan Plywood’s Importance

Lauan plywood’s popularity is significant, with its uses spanning construction, furniture-making, cabinetry, and even packaging. One of the major reasons for its widespread use is its ability to balance cost with performance. In industries like furniture-making, lauan plywood is favored for projects where both appearance and durability are important, such as cabinet making and decorative applications. Additionally, due to its relatively lower price compared to higher-end hardwoods, it is often the go-to material for projects on a budget without compromising too much on quality.

In construction, lauan plywood serves as an underlayment for flooring, an essential component for providing a stable and smooth surface. It is also used for wall paneling, providing a consistent, aesthetically pleasing finish for both commercial and residential spaces. As more sustainable and eco-conscious sourcing practices develop, lauan plywood has even become more desirable for those looking to incorporate responsible materials into their projects.

Origin and Source of Lauan Plywood

Geographic Origin

When someone asks, «What is plywood made from lauan wood?» it’s important to note that lauan plywood is sourced predominantly from tropical forests in Southeast Asia. The Philippines, Indonesia, and Malaysia are the primary exporters of lauan wood. These regions are rich in the Shorea genus of trees, which are key to the production of lauan plywood.

The specific geographical origin of the wood impacts its characteristics. Southeast Asia is home to vast rainforests, which provide the ideal climate and conditions for the growth of Shorea trees, yielding wood that is ideal for veneer production. This region’s warm temperatures and consistent rainfall allow the trees to grow steadily, contributing to their quality.

The Lauan Tree

What type of wood is used in lauan plywood? The answer lies in the Shorea trees of Southeast Asia. These trees produce the lauan timber that is used to manufacture plywood. These trees, while not true mahogany, are often referred to as Philippine mahogany due to their similar appearance and qualities. Lauan wood has a fine, straight grain and a smooth surface, making it perfect for slicing into veneers.

The Shorea genus consists of several species, each with slightly different wood characteristics, but they all share qualities that make them suitable for plywood production. The wood is relatively lightweight, yet strong, which makes it a good option for applications where both strength and ease of handling are important. The color of lauan wood ranges from a light reddish-brown to a deeper brown, giving it a warm and natural look when used in finished products.

Historical Background

The history of lauan plywood dates back to the mid-20th century when it became a major export product from Southeast Asia. Lauan wood was recognized for its strength and beauty, and it quickly became popular in global markets. Over time, the production of lauan plywood expanded, and its uses grew in industries such as construction, furniture, and interior design. What once started as a regional resource has now become a material with international significance.

As demand for lauan plywood increased, the processes for harvesting and producing it were refined. This included developing methods to slice the wood into thin veneers and improving the bonding techniques to create high-quality plywood sheets. Today, the production of lauan plywood is a global industry, with strict regulations in place to ensure the wood is sourced sustainably.

Production Process of Lauan Plywood

Raw Material Selection

So, what does lauan plywood refer to in terms of raw materials? The process of making lauan plywood begins with the careful selection of trees. Manufacturers look for mature Shorea trees that are free from defects, such as knots or splits. The quality of the raw material is key to producing high-quality plywood. The trees must be strong and stable, with a smooth grain that will allow them to be sliced into thin, uniform veneers.

Sustainability has become a growing concern in recent years, and many manufacturers now prioritize sourcing lauan timber from responsibly managed forests. The Forest Stewardship Council (FSC) certification, for example, ensures that the wood is harvested in a way that minimizes environmental impact and supports long-term forest health.

Lamination and Veneer Process

The process of turning lauan wood into plywood begins by slicing the logs into thin veneers, which are typically between 1 and 3 millimeters thick. These veneers are then layered on top of one another in a crisscross pattern, with each layer’s grain running perpendicular to the one beneath it. This cross-grain layering helps improve the plywood’s strength and stability.

Once the layers are aligned, they are glued together using a strong adhesive that bonds the wood fibers. Heat and pressure are often applied during this step to ensure the layers bond firmly and that the plywood has a uniform thickness throughout. This process ensures that the plywood will have good structural integrity and durability for a variety of applications.

Manufacturing Methods

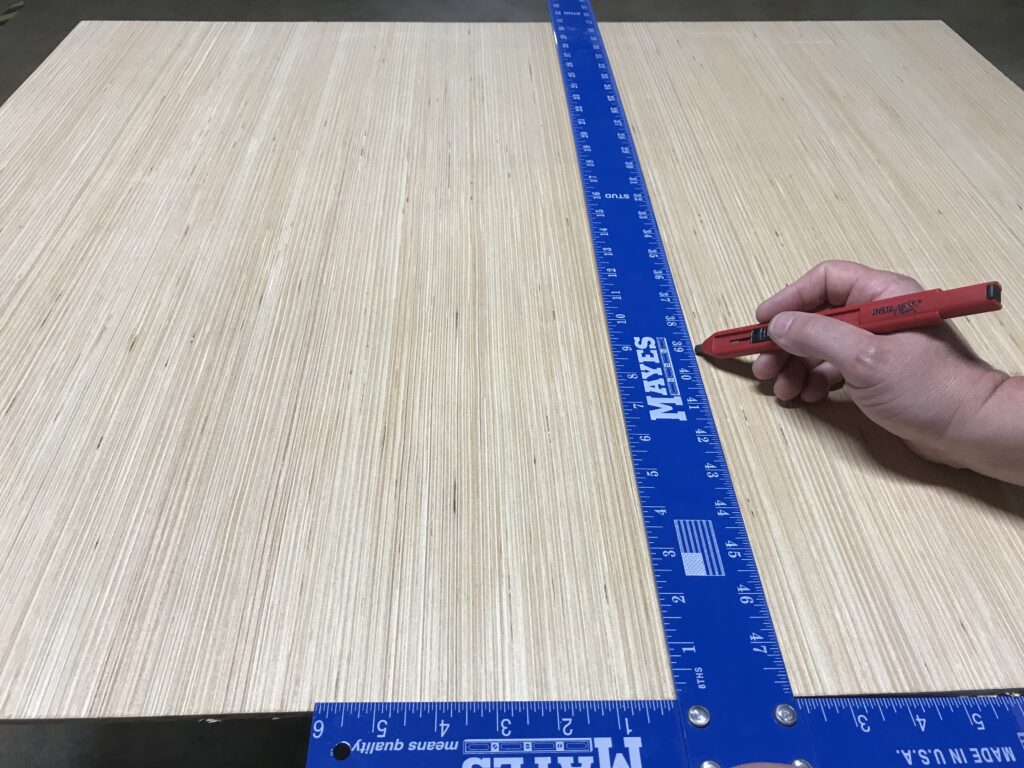

Lauan plywood is manufactured using advanced machinery that helps ensure precision in every stage of production. The logs are first debarked, and then they are sliced into veneers using rotary or slicer methods, depending on the desired texture of the plywood. After the veneers are cut, they are sorted based on quality, with the best-quality sheets reserved for higher-grade plywood.

Adhesives are applied to the veneers, which are then stacked and pressed under heat to bond the layers. Depending on the manufacturer, some mills may use a hot press, which allows the glue to set quickly and ensures a strong bond. Some manufacturers also use cold presses or even vacuum presses to achieve a more uniform bond.

Quality Control

Quality control is a critical aspect of the production of lauan plywood. Each sheet of plywood must meet strict standards to ensure its durability and performance. The plywood is tested for various properties, including its resistance to moisture, flexibility, and overall strength. Any defects, such as warping or air bubbles between the layers, are identified and corrected before the plywood is shipped.

The final product is often subjected to visual inspection as well, checking for consistency in appearance and texture. Lauan plywood manufacturers take pride in ensuring that their product meets or exceeds industry standards, particularly in regard to aesthetics and functionality.

Characteristics of Lauan Plywood

Wood Properties

Lauan plywood has several characteristics that make it distinct from other types of plywood. One of the primary factors is its appearance. The wood used to make lauan plywood is known for its fine grain and smooth texture, which gives the plywood an elegant and natural look. Its color typically ranges from light to medium reddish-brown, although the shade can vary depending on the specific species of Shorea used.

The plywood is generally smooth and easy to finish, whether it is stained, painted, or left in its natural state. Its fine grain makes it an excellent choice for decorative applications, particularly in furniture-making and wall paneling.

Durability and Strength

Lauan plywood offers a strong balance of durability and lightweight properties, which makes it versatile for a range of uses. It is strong enough for most interior applications, such as flooring underlayment, cabinetry, and furniture, but it is not as dense or as heavy as other hardwood plywoods like oak or maple. This makes it easier to handle during construction and furniture-making projects.

While lauan plywood is durable for many uses, it may not be the best choice for applications that require extreme strength or resistance to high levels of wear and tear. For heavy-duty uses like exterior construction or high-traffic areas, other plywood types might be better suited.

Moisture Resistance

One of the drawbacks of lauan plywood is its lower moisture resistance compared to other types of plywood. While it does have some resistance to moisture, it is not as well-suited for outdoor or marine applications as marine-grade plywood or other species like birch, which naturally have higher moisture resistance.

If lauan plywood is used in damp or humid environments, such as kitchens or bathrooms, it is recommended to apply a protective finish to help mitigate the effects of moisture. For applications where the plywood will be exposed to water regularly, such as in boat building or exterior structures, marine-grade plywood would be a better choice.

Surface Finish and Aesthetics

The fine grain and smooth texture of lauan plywood make it an attractive option for decorative purposes. Its surface finish is ideal for applications such as cabinetry, wall paneling, and furniture. Lauan plywood takes stains and paints well, allowing it to be customized to suit different design preferences.

Due to its smooth finish and relatively uniform texture, lauan plywood is a popular choice for projects that require both form and function. It can easily be stained to bring out the natural color or painted to match the surrounding décor.

Uses and Applications of Lauan Plywood

Common Applications

Lauan plywood is incredibly versatile and can be used for a wide range of applications in various industries. Some of the most common uses of lauan plywood include:

- Furniture Making: Due to its smooth finish and attractive appearance, lauan plywood is commonly used to make furniture, including tables, chairs, and cabinets. Its lightweight nature makes it easier to work with, while its durability ensures that it will last for years.

- Interior Wall Paneling: Lauan plywood is a popular choice for interior wall paneling, as it creates a sleek, modern look. It can be stained or painted to match the design of a room, and its easy-to-work-with nature makes it a favorite for both DIY enthusiasts and professionals.

- Cabinetry: Lauan plywood’s smooth finish and strength make it a great option for constructing cabinets. It’s often used in kitchens, bathrooms, and storage areas due to its affordability and ease of customization.

- Flooring Underlayment: Lauan plywood is commonly used as an underlayment for flooring projects. It provides a stable and smooth surface for laying flooring, ensuring the final floor is level and durable.

- Packaging and Shipping: Due to its affordability and strength, lauan plywood is often used in packaging materials, such as crates and pallets. This ensures that goods are protected during transportation and storage.

- Marine Construction: While it is not the most commonly used plywood in marine construction, lauan plywood does find some use in boat-building projects and dock construction, where a more economical option is required.

Advantages in Construction and Design

Lauan plywood’s popularity can be attributed to several advantages it offers in construction and design. Its cost-effectiveness allows builders and designers to achieve a high-quality finish without breaking the budget. It’s lightweight, which makes it easy to handle during installation, and it’s versatile enough for a range of projects. Whether used for structural purposes or as a decorative element, lauan plywood’s combination of form and function makes it a preferred choice in many industries.

Types of Lauan Plywood

Different Grades of Lauan Plywood

Lauan plywood comes in different grades, with higher-grade sheets having fewer defects and imperfections. The grading system for lauan plywood typically includes A, B, C, and D grades, with A being the highest quality. A-grade plywood is smooth and free of imperfections, making it ideal for decorative purposes. Lower grades, like C and D, may contain more visible defects but can still be used for structural applications.

Marine Grade vs. Standard Lauan Plywood

One distinction between different types of lauan plywood is the difference between standard and marine-grade lauan plywood. Marine-grade plywood is specially treated to improve its moisture resistance, making it suitable for use in damp or water-exposed environments, such as boat building. While standard lauan plywood is not as moisture-resistant, it can still be used in interior applications or places where moisture exposure is minimal.

Sustainability and Environmental Impact

Sourcing Practices

The sustainability of lauan plywood has been a topic of concern in recent years, particularly because it is sourced from tropical forests in Southeast Asia. Unsustainable logging practices can lead to deforestation, which threatens biodiversity and contributes to climate change. However, many manufacturers are now committed to sustainable sourcing practices, and many suppliers offer FSC-certified lauan plywood, which ensures the wood comes from responsibly managed forests.

Sustainability Certifications

To ensure that the lauan plywood used in construction and design projects is sustainably sourced, it is important to look for certifications like the Forest Stewardship Council (FSC). FSC certification guarantees that the plywood is made from wood harvested in an environmentally responsible way, with minimal impact on the ecosystem. Other certifications may also be available, depending on the region or supplier, to further validate the environmental credentials of the product.

Environmental Concerns

Despite efforts to make lauan plywood production more sustainable, there are still concerns about the environmental impact of its manufacture. Deforestation remains an issue in some parts of Southeast Asia, and the use of chemicals in plywood production can contribute to pollution if not properly managed. By choosing certified sustainable plywood and supporting companies with transparent sourcing practices, consumers can help mitigate these environmental impacts.

Conclusion

Summary of Key Points

In conclusion, lauan plywood is an essential material in many industries, particularly in construction, furniture-making, and interior design. Its lightweight nature, durability, and aesthetic qualities make it a popular choice for various applications, from cabinetry and furniture to flooring and packaging. While it may not be as moisture-resistant as other types of plywood, it offers an affordable and versatile solution for many indoor projects.

Final Thoughts on Lauan Plywood

Lauan plywood’s popularity continues to grow, and as sustainable sourcing practices improve, its environmental impact will continue to decrease. Whether you are working on a home improvement project, building furniture, or tackling a larger construction endeavor, understanding what lauan plywood is and how to use it effectively can help you make the best choices for your project. By focusing on quality, sustainability, and the wide range of applications, lauan plywood remains a dependable material for both professionals and DIY enthusiasts alike.