When constructing or replacing a roof, selecting the correct plywood thickness is one of the most essential decisions you’ll face. Plywood serves as the backbone of many roofing systems, providing structural support and serving as a base for roofing materials such as shingles, tiles, or metal. It is critical to understand that the right plywood thickness for your roof will directly impact the strength, durability, and performance of the roof as a whole. If you select plywood that is too thin or too thick, it could lead to structural issues or unnecessary costs.

This comprehensive guide is designed to help homeowners, contractors, and builders determine what thickness plywood for roof construction will best suit their needs. We will cover everything from the different types of plywood used in roofing to the factors that influence your decision on plywood thickness. Whether you’re installing a roof for a residential property or commercial building, knowing the correct plywood thickness can ensure a solid, long-lasting roof structure.

The Importance of Choosing the Right Plywood Thickness for Roofing

The plywood thickness you choose for your roof plays a crucial role in the overall performance and stability of your roof. Choosing the right thickness helps ensure that your roof can bear the load of the roofing material itself, any snow or rain it may encounter, and any additional weight or environmental stress. Whether you are repairing a roof or starting a new construction project, selecting the appropriate plywood thickness guarantees your roof will withstand the tests of time and weather conditions.

While plywood is a commonly used roofing material, its thickness is not one-size-fits-all. It must be selected carefully, taking into account the specifics of the roof design, local weather conditions, and the type of roofing material you plan to use. In the sections to follow, we will delve into the factors that affect plywood thickness selection and explain the ideal thickness for a variety of roofing types and conditions.

What Is Plywood and Why Is It Used in Roofing?

Composition of Plywood

Plywood is made by bonding multiple thin layers of wood, or «plies,» together with adhesive. The grain of each layer runs in a different direction to enhance strength and prevent warping. This unique construction makes plywood a strong and durable material that is ideal for use in roofing. In roofing applications, plywood is valued for its ability to provide structural stability without adding excessive weight to the roof.

Plywood’s layered design gives it several advantages over solid wood. It is more resistant to splitting and shrinking, which is crucial when dealing with the moisture and temperature fluctuations that roofs are exposed to. Additionally, plywood offers a great strength-to-weight ratio, making it an efficient material for roofing without compromising on durability.

Benefits of Using Plywood in Roofing

- Strength and Durability: The multi-layer construction of plywood ensures it can withstand heavy loads, such as snow, rain, and wind. It is especially valuable for roofing, where structural integrity is crucial for long-term performance.

- Affordability: Compared to other materials like steel or solid wood planks, plywood is relatively inexpensive. This makes it a cost-effective choice for both homeowners and contractors looking to build or replace roofs.

- Versatility: Plywood is available in a range of grades and thicknesses, making it suitable for different types of roofs, whether residential or commercial. It can be cut to size easily and installed quickly, which makes it highly versatile for various roofing applications.

You might be interested in this article: What Type of Plywood for Subfloor?

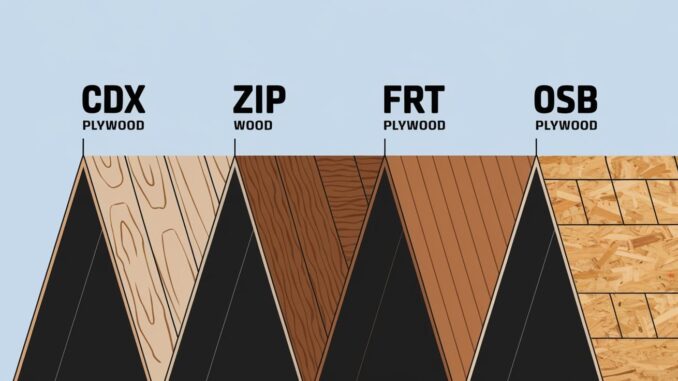

Types of Plywood for Roofing

Plywood is available in several different grades, with each type offering distinct benefits for roofing:

- Exterior Grade Plywood: This is the most commonly used type of plywood for roofing, specifically because it is designed to withstand outdoor conditions. The plywood is treated with adhesives that can resist moisture, ensuring that the material remains stable and durable even under extreme weather conditions.

- CDX Plywood: CDX plywood is one of the most popular choices for roofing projects. It is a budget-friendly option that is rated for exterior use and comes with a «C» and «D» grading for its veneer. While it may not have the finest appearance, CDX plywood provides the necessary strength for most roofing applications.

- Marine-Grade Plywood: In areas where high moisture levels are a concern, marine-grade plywood may be the best option. This type of plywood is specially treated to resist water damage, rot, and decay, making it ideal for roofing in humid or coastal environments.

Common Roofing Applications

Plywood plays an important role in several key parts of a roof:

- Roof Decking: Plywood is used as the base layer for roofing materials like asphalt shingles, tiles, or metal panels. It provides a solid foundation for the roofing material to adhere to and protects the structural integrity of the roof.

- Sheathing: Plywood sheathing is placed over the roof rafters to provide structural support for the roof. It helps distribute the load of the roofing material evenly across the entire roof.

- Underlayment: Plywood can also serve as underlayment, providing an additional layer of protection beneath the roofing material. This is particularly important in areas prone to heavy rain or high winds.

Factors to Consider When Choosing Plywood Thickness for Roofing

Roof Span and Spacing

The distance between roof supports, such as rafters or trusses, plays a critical role in determining what thickness plywood for roof installation is best. The wider the span between supports, the thicker the plywood needs to be to prevent sagging and maintain structural integrity. In general, when the rafters are spaced further apart, thicker plywood will be required to provide adequate support.

For example, if the rafters are spaced 24 inches apart, you may need to use thicker plywood, such as 5/8-inch or 3/4-inch, to ensure the roof remains stable. If the rafters are spaced closer together (e.g., 16 inches apart), you can usually use thinner plywood, such as 1/2-inch, without compromising the roof’s strength.

Load and Structural Considerations

The weight that the roof structure will bear is another crucial factor in determining the appropriate plywood thickness. Roofs must be able to support not only the weight of the roofing materials themselves but also additional loads such as snow, rain, and foot traffic. In areas where heavy snow or rain is common, you will need thicker plywood to ensure the roof can handle these extra stresses.

Additionally, structural considerations such as the type of roofing material you plan to use may influence your plywood thickness. Heavier roofing materials like tile or slate may require thicker plywood to support the added weight, while lighter materials like asphalt shingles may not need as much thickness.

Climate and Weather Conditions

Environmental factors like extreme weather conditions can significantly impact your plywood thickness decision. In areas prone to high winds, heavy snow, or intense heat, you’ll need plywood that can withstand the added stress. The plywood should be thick enough to resist the forces exerted on it during strong storms or when subjected to heavy snow loads.

If you live in a region with particularly harsh conditions, you may want to opt for thicker plywood, such as 5/8-inch or 3/4-inch, to ensure that the roof is durable enough to handle the stresses of your local climate.

Type of Roofing Material

The roofing material you plan to use also affects the plywood thickness selection. Heavier materials like metal roofing or clay tiles place more stress on the roof structure and require thicker plywood. Asphalt shingles, on the other hand, are lighter and may allow you to use thinner plywood without sacrificing performance.

By choosing the appropriate plywood thickness based on your roofing material, you can ensure that the roof provides sufficient support for years to come.

You might be interested in this article: How Many Sheets of Plywood in a Bundle?

Building Codes and Regulations

Adhering to local building codes is essential when selecting plywood thickness for your roof. Building codes are designed to ensure safety and structural integrity, and they often include guidelines for the minimum plywood thickness required for different types of roofs. These codes take into account factors such as local weather conditions, roof design, and load-bearing requirements.

Consulting local building codes is crucial to avoid potential fines or safety issues. If you’re unsure about what thickness plywood for roofing is required by your building codes, consider consulting with a local professional who can help you navigate these regulations.

Common Plywood Thicknesses for Roofing

1/4-Inch Plywood

1/4-inch plywood is generally used for light applications, such as roof underlayment or thin sheathing. This thickness is typically used for roofs with close rafter spacing and minimal load-bearing requirements. It is not ideal for roofs that will experience heavy snow, wind, or other environmental stresses. However, it may be suitable for temporary roofs or low-slope roofs that will not bear significant loads.

3/8-Inch Plywood

3/8-inch plywood is often used for roof sheathing in applications where the rafters are spaced closer together. This thickness provides a balance of strength and affordability, making it a popular choice for many residential roofing projects. It is suitable for roofs with moderate load-bearing requirements and is a good option for homeowners on a budget.

1/2-Inch Plywood

1/2-inch plywood is a common choice for residential roofs. It strikes a good balance between strength and weight, making it suitable for a wide range of roofing applications. This thickness is typically used for roofs with standard rafter spacing (16 to 24 inches apart) and moderate load-bearing requirements. 1/2-inch plywood is often chosen for its cost-effectiveness and durability.

5/8-Inch Plywood

5/8-inch plywood is ideal for roofs with longer spans or additional load-bearing requirements. This thickness provides added stability and is often used in areas where heavy snow loads are common. It is also a good option for roofs that will experience high winds or other extreme weather conditions. If your roof requires extra strength or stability, 5/8-inch plywood may be the best option.

3/4-Inch Plywood

3/4-inch plywood is typically used for roofs with wide rafters or in areas with extreme weather conditions. This thicker plywood provides superior strength and durability, making it ideal for roofs that need to support heavy snow loads or endure high winds. While it is more expensive and heavier than thinner plywood, it offers enhanced performance and protection for larger or more demanding roofing projects.

How to Determine the Right Thickness Based on Roof Design

Flat Roofs vs. Pitched Roofs

The design of the roof itself plays a significant role in determining what thickness plywood for roof decking is necessary. Flat roofs generally require thicker plywood than pitched roofs, as flat roofs have a more even load distribution. Since they are prone to pooling water, the plywood must be strong enough to support the added weight of the water and prevent sagging or structural issues.

In contrast, pitched roofs distribute weight more efficiently due to their angled design. This allows for the use of thinner plywood without compromising structural integrity. However, steeply pitched roofs may require thicker plywood to ensure proper load distribution and to withstand high winds.

You might be interested in this article: What is RTD Plywood?

Roof Pitch and Slope

Roof pitch refers to the steepness or angle of the roof. The steeper the roof pitch, the more load it can handle, which may influence the choice of plywood thickness. For example, a roof with a high pitch may be able to support a lighter thickness of plywood because the angle reduces the stress placed on the material. On the other hand, a flatter roof may require thicker plywood to prevent sagging or structural failure.

Rafter Spacing

The spacing between rafters directly impacts plywood thickness selection. Standard rafter spacing is typically 16 inches or 24 inches, but wider spacing requires thicker plywood to prevent sagging between rafters. For example, if your rafters are spaced 24 inches apart, you’ll likely need to use 5/8-inch or 3/4-inch plywood to maintain the roof’s strength and durability.

Plywood Grades for Roofing

Exterior vs. Interior Grades

When selecting plywood for roofing, it is essential to choose exterior-grade plywood. Unlike interior-grade plywood, which is not designed to withstand the elements, exterior-grade plywood is treated to resist moisture and can handle the stresses of outdoor environments. This ensures that the plywood will remain intact and provide a strong foundation for the roof, even in harsh weather conditions.

CDX Plywood

CDX plywood is a common choice for roofing due to its affordability and durability. It is rated for exterior use and features veneers that are glued together with weather-resistant adhesives. While it may not be as aesthetically pleasing as higher-grade plywood, CDX plywood provides the necessary strength and resistance to weather conditions, making it an ideal option for most residential roofing projects.

Marine-Grade and Other Specialty Plywood

Marine-grade plywood is specially treated to resist water damage, rot, and decay, making it suitable for environments with high moisture levels. This type of plywood is often used in coastal regions or areas with high humidity. Marine-grade plywood is more expensive than standard exterior-grade plywood but offers superior durability in extreme conditions.

Advantages and Disadvantages of Using Thicker Plywood

Benefits of Thicker Plywood

- Increased Strength: Thicker plywood provides better load-bearing capacity, which is essential for roofs with wide spans or heavy load requirements.

- Better Load Distribution: Thicker plywood helps distribute weight evenly across the roof, preventing sagging or structural failure.

- Improved Durability: Thicker plywood is more resistant to wear and tear from the elements, offering a longer lifespan for your roof.

Drawbacks of Thicker Plywood

- Increased Weight: Thicker plywood adds more weight to the roof, which can increase the load on the structure and may require additional support.

- Higher Cost: Thicker plywood is generally more expensive than thinner options, which can increase the overall cost of the roofing project.

How to Install Plywood for Roofing

Once you’ve chosen the correct plywood thickness for your roof, the next step is proper installation. Installing plywood correctly ensures that your roof remains strong, durable, and weather-resistant for years to come. Here are the key steps involved in installing plywood for roofing.

Preparing the Roof Deck

Before you begin laying down plywood, it is crucial to prepare the roof deck. This involves removing any old roofing materials, cleaning the surface, and making sure that the deck is level and free of debris. A clean and smooth deck ensures that the plywood will be securely fastened and that the roofing material will adhere properly. If the roof deck is uneven, you may need to correct any imperfections or install additional supports to ensure proper plywood installation.

Spacing Between Plywood Sheets

When installing plywood, it is important to leave the proper amount of space between each sheet. The typical gap is 1/8-inch, which allows the plywood to expand and contract due to changes in temperature and moisture. This expansion and contraction are especially important in regions with extreme weather conditions, where the plywood may be subjected to heavy moisture or heat. Leaving adequate spacing between sheets helps prevent buckling and warping over time.

Fastening and Securing Plywood

Once the plywood sheets are in place, they need to be securely fastened to the roof rafters or trusses. The best method for fastening plywood is to use corrosion-resistant nails or screws, especially in coastal areas where saltwater can cause rusting. Ensure that the fasteners are placed approximately 6 to 8 inches apart along the edges of the plywood sheets and 12 inches apart in the interior sections.

It’s important to use the correct type and size of fasteners to ensure a strong hold. If you’re unsure which fasteners to use, consult with a professional or refer to local building codes for guidance.

You might be interested in this article: What is Sheathing Plywood?

Sealing and Waterproofing

Once the plywood is installed and fastened, you should seal the edges and joints of the plywood sheets to enhance their water resistance. This is especially important for exterior-grade plywood, as it is more exposed to the elements. Use a waterproofing sealant along the edges of the plywood to protect against water infiltration. This step helps prevent rot, mold, and other moisture-related issues that could compromise the integrity of your roof.

After sealing the plywood, you can proceed to install the roofing material of your choice, whether it’s shingles, metal panels, or another option. The plywood will serve as a sturdy base for the roofing material and provide structural support.

Alternatives to Plywood for Roofing

While plywood is a popular choice for roofing, there are several alternatives that may be more suitable for specific roofing needs. Each alternative material comes with its own advantages and disadvantages.

OSB (Oriented Strand Board)

Oriented Strand Board (OSB) is another material commonly used in roofing. It is made by compressing wood strands with adhesive to form large sheets. OSB is often used as a cost-effective alternative to plywood, as it is cheaper but still provides a strong foundation for roofing materials. However, OSB is not as moisture-resistant as plywood, which can be a concern in areas with high humidity or heavy rainfall.

Solid Wood Planks

Historically, solid wood planks were used for roofing before plywood became the go-to option. Solid wood planks provide excellent support and are still used in some roofing applications, especially in historic homes or buildings with specific aesthetic needs. However, solid wood planks are more expensive and prone to warping or splitting over time. Plywood, with its superior strength-to-weight ratio, has largely replaced solid wood planks in most modern roofing systems.

Metal Roof Decking

Metal decking is another alternative to plywood, often used in commercial or industrial roofing projects. It is typically made from galvanized steel or aluminum and provides excellent durability and fire resistance. Metal roof decking is ideal for buildings that require a high level of strength and protection, but it is more expensive and requires specialized installation techniques. It’s not a typical choice for residential roofing, but it can be an option for specific commercial or high-performance applications.

Common Mistakes to Avoid When Choosing Plywood Thickness for Roof

Choosing the correct plywood thickness is critical for ensuring the durability and stability of your roof. However, there are several common mistakes that people make when selecting plywood for roofing. Avoiding these errors will save you time, money, and effort in the long run.

Underestimating Roof Load

One of the most common mistakes is underestimating the load that the roof will need to support. This can happen if you choose plywood that is too thin for the weight of the roofing material or the environmental conditions. If you live in an area with heavy snow, high winds, or frequent storms, your roof will need thicker plywood to handle the additional load. Always account for these factors when choosing your plywood thickness to avoid structural failure down the line.

You might be interested in this article: How Much Weight Can Plywood Hold?

Neglecting Building Codes

Another mistake is failing to adhere to local building codes and regulations. Building codes are in place to ensure that structures are safe and stable, and they often include guidelines for minimum plywood thickness. By neglecting these codes, you risk compromising the safety of the roof, which could lead to costly repairs or legal issues. Be sure to consult with local authorities or professionals to ensure that your plywood thickness meets the required standards.

Using the Wrong Plywood Grade

Not all plywood is suitable for roofing applications. Using interior-grade or low-quality plywood for roofing can result in premature deterioration, water damage, and structural failure. It is essential to use exterior-grade plywood or CDX plywood, both of which are designed to withstand the elements. Always verify that the plywood you’re using is rated for outdoor use to ensure long-term durability.

Conclusion

Summary of Key Points

Choosing the right plywood thickness for your roof is essential for ensuring a strong, durable, and long-lasting roof structure. Several factors influence this decision, including the roof span, load-bearing requirements, climate conditions, and the type of roofing material being used. Thicker plywood may be necessary for roofs with wider spans or in areas prone to extreme weather conditions, while thinner plywood can suffice for lighter roofing applications.

Always consider the specific needs of your roofing project and adhere to local building codes to ensure your roof will be safe and stable. Whether you choose 1/4-inch plywood for light applications or 3/4-inch plywood for more demanding roofs, proper installation is crucial for maximizing the performance and longevity of your roof.

Final Recommendation

When in doubt, consult with a roofing professional or contractor to help you determine the most suitable plywood thickness for your roofing project. By selecting the right plywood thickness, you can be confident that your roof will provide lasting protection and support for years to come.

Call to Action

If you’re planning a roofing project, take the time to evaluate your specific needs and choose the appropriate plywood thickness for roofing. Don’t hesitate to consult with a professional to ensure your roof will be safe, durable, and capable of withstanding the elements.

Frequently Asked Questions (Optional)

Is 1/2-inch plywood thick enough for a roof?

1/2-inch plywood is often sufficient for residential roofs with standard rafter spacing and moderate load-bearing requirements. However, if your roof is exposed to heavy snow, wind, or extreme conditions, you may need to opt for thicker plywood, such as 5/8-inch or 3/4-inch.

Can I use thinner plywood for my roof if I have closer rafter spacing?

Yes, if your rafters are spaced closer together, you may be able to use thinner plywood without sacrificing strength. For example, with rafter spacing of 16 inches, 1/2-inch plywood is often sufficient. However, always consider the load and environmental factors before making a decision.

What is the best plywood thickness for a shed roof?

For a shed roof, 1/2-inch or 5/8-inch plywood is typically ideal. If the roof will bear heavy loads, or if you live in an area with heavy snow or wind, consider using 5/8-inch or thicker plywood for added strength.

How do I know if my roof needs thicker plywood?

If your roof is in an area with heavy snowfall, high winds, or extreme temperatures, or if the rafters are spaced widely apart, you may need thicker plywood. Always factor in the load-bearing capacity and climate conditions when selecting plywood thickness for your roof.